In today's fast-paced manufacturing landscape, the demand for efficiency and cost-effectiveness has never been more pressing. As industries strive to reduce lead times and streamline production processes, the adoption of rapid tooling has emerged as a game-changing solution. According to a report by the CIMdata, rapid tooling can reduce production time by as much as 50% compared to traditional methods while also significantly lowering costs associated with material procurement and labor.

This paradigm shift not only enables manufacturers to respond quickly to market changes but also enhances their ability to innovate. As companies grapple with challenges such as supply chain disruptions and increasing customization demands, understanding the myriad benefits of rapid tooling becomes essential for staying competitive. In this blog, we will explore the inherent problems associated with traditional tooling and illustrate how rapid tooling addresses these issues to unlock new efficiencies in modern manufacturing solutions.

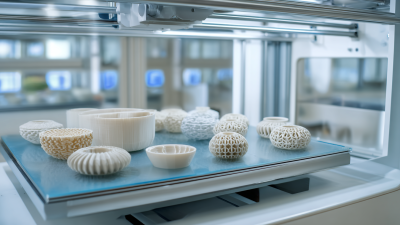

In today's fast-paced manufacturing landscape, the pressure to reduce time to market has never been greater. Rapid tooling is emerging as a transformative solution, enabling companies to streamline their production processes significantly. By utilizing advanced manufacturing technologies such as 3D printing and computer-aided design, businesses can create tooling and prototypes much more quickly than traditional methods would allow. This rapid approach not only shortens the development cycle but also allows for more iterations throughout the design process, resulting in a product that better meets customer needs.

The benefits of rapid tooling extend beyond just speed. With faster prototyping, manufacturers can more effectively respond to market demands and accelerate their innovation cycles. This increased agility helps companies stay competitive, as they can introduce new products and modifications faster than their rivals. Additionally, the cost savings associated with rapid tooling are substantial; it reduces labor and material waste and optimizes resource allocation. As a result, businesses can focus their investments on design improvements and quality enhancements, further driving efficiency and growth within the manufacturing sector.

The demand for risk reduction in manufacturing is more critical than ever, with effective decision-making playing a pivotal role in market growth. Rapid tooling offers a cost-effective solution that not only drives down production expenses but also mitigates risks associated with complex systems. Advanced simulation software enables businesses to evaluate potential bottlenecks and weaknesses early in the development cycle. For instance, the high numerical aperture EUV lithography equipment, despite its almost $400 million price tag, can significantly reduce overall production costs when applied appropriately.

Tips for manufacturers looking to optimize their operations include exploring supply chain optimization strategies to enhance efficiency and customer satisfaction. By focusing on areas such as inventory management and process alignment, companies can streamline costs while maintaining agility. Furthermore, understanding the nuances of tool selection in market trends, such as the projected growth of downhole tools by 2032, is vital for making informed investments. Balancing innovation with practical applications is key to unlocking the full potential of rapid tooling in modern manufacturing solutions.

| Dimension | Value |

|---|---|

| Increased Production Speed | 30% Reduction in Production Time |

| Cost Savings | 15% Decrease in Manufacturing Costs |

| Material Waste Reduction | 20% Less Material Waste |

| Prototype Development Time | 50% Faster Prototyping |

| Flexibility in Design Changes | Instant Adaptability to Design Modifications |

| Production Scalability | Rapid Scale-Up Capabilities |

In today's fast-paced manufacturing environment, companies face the constant challenge of adapting to ever-evolving market demands. Enhanced design flexibility is no longer a luxury but a necessity. Rapid tooling offers manufacturers the ability to pivot quickly, enabling real-time adaptation to customer preferences and market conditions. According to a report by PWC, 72% of manufacturers believe that technological advancements, including rapid tooling, will significantly impact their ability to respond to market changes.

One notable benefit of rapid tooling is the reduction in lead times. Traditional tooling methods can take weeks or even months to produce. In contrast, rapid tooling techniques can slash this time to mere days, allowing companies to bring their products to market faster. For example, a survey by Deloitte found that 92% of manufacturers who adopted rapid tooling reported improved project turnaround times, resulting in better customer satisfaction and increased sales.

Tips: Embrace modular design approaches to enhance product adaptability. Consider integrating design software that allows for quick modifications and simulations. Additionally, involve customers in the design process to better align products with their needs—this can lead to increased loyalty and repeat business.

In the realm of modern manufacturing, the integration of rapid prototyping has emerged as a pivotal advancement, ensuring quality improvement while significantly reducing errors and wastage. By allowing designers and engineers to quickly create prototypes, rapid tooling facilitates an iterative feedback loop that accelerates the development process. This approach not only enhances the overall functionality of products but also serves to identify and rectify potential design flaws early in the production cycle, minimizing costly errors down the line.

The strategic advantage of rapid prototyping lies in its ability to streamline workflows and foster innovation. As manufacturers embrace technologies that support quick turnaround times, they can maintain competitive agility in the ever-evolving market landscape. This adaptability not only increases efficiency but also empowers engineering teams to focus on user-centric design principles, ultimately leading to products that are better aligned with customer needs and preferences. In an age where user experience and interface design play crucial roles, leveraging rapid tooling becomes an essential strategy for achieving high-quality outcomes in modern manufacturing solutions.

The adoption of rapid tooling in modern manufacturing solutions has been gaining significant momentum, driven by the need for faster production cycles and cost-effective processes. According to a report by Deloitte, the market for rapid tooling is expected to grow at a compound annual growth rate (CAGR) of 25% through 2025. This surge is primarily attributed to industries prioritizing streamlined operations and reduced time-to-market for products.

Furthermore, a survey conducted by the 3D Printing Industry has found that 62% of manufacturers are now incorporating rapid tooling techniques into their workflows. This shift reflects a broader industry trend where businesses are recognizing the benefits of additive manufacturing and quick turnaround times. The integration of rapid tooling not only enhances the efficiency of prototype development but also optimizes production by minimizing material waste and labor costs. As more companies embrace these innovative solutions, the landscape of manufacturing is transforming, aligning with the demands for increased flexibility and responsiveness in production.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |