As we look towards 2025, the field of rapid 3D printing is poised for transformative advancements that will reshape various industries. Industry expert Dr. Emily Chen, a leading figure in additive manufacturing, emphasizes the potential of this technology by stating, “Rapid 3D printing is not just about making products faster; it’s about rethinking how we design and produce in the modern world.” This insight highlights the shift from traditional manufacturing paradigms to innovative, efficient practices enabled by rapid 3D printing.

The trends projected for the near future, such as increased speed, improved materials, and sophisticated software integration, will enhance the capabilities of rapid 3D printing. As businesses seek greater efficiency and sustainability, understanding these trends will be crucial for staying competitive. The convergence of artificial intelligence and rapid 3D printing technologies promises to optimize production processes further, allowing for on-demand manufacturing that meets consumer needs more effectively.

In summary, the evolution of rapid 3D printing is not merely a technological progression; it represents a fundamental change in the way we conceive of manufacturing. By exploring the key trends shaping this industry in 2025, stakeholders can prepare to leverage these innovations for their strategic advantage in the global market.

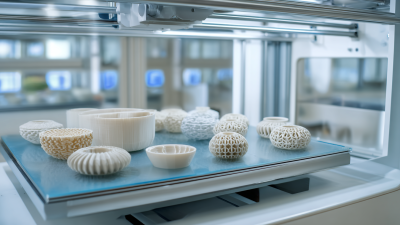

The landscape of 3D printing technology is set to undergo significant transformations by 2025, particularly with the emergence of innovative materials designed to enhance performance. According to a recent report by Wohlers Associates, the global 3D printing materials market is projected to reach $3.8 billion by 2025, indicating a robust investment in superior material development. These newly developed materials are designed not only to improve mechanical properties but also to expand the range of applications in various industries, including aerospace, automotive, and healthcare. For instance, metals, ceramics, and bio-compatible polymers are leading the charge, offering enhanced durability and functionality suitable for highly specialized applications.

As companies and researchers delve into the vast possibilities of 3D printing materials, it is essential to adapt quickly to these advancements. One key tip is to stay informed about innovations in material science, as knowledge of new composites or alloys could provide a competitive edge. Additionally, integrating sustainable practices, such as using recycled materials or biodegradable options, can play a crucial role in attracting environmentally conscious consumers and complying with evolving regulations.

Furthermore, collaboration across different sectors can foster the development of hybrid materials that combine characteristics from multiple sources, yielding superior performance. As the 3D printing landscape continues to evolve, being proactive about understanding material capabilities and fostering interdisciplinary partnerships will be vital for staying ahead in this dynamic field.

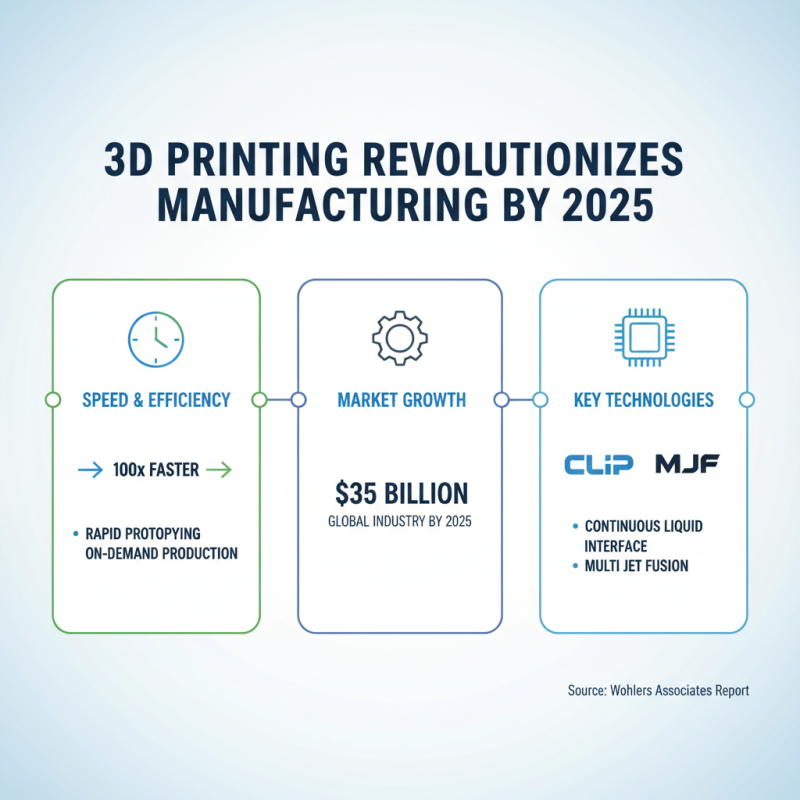

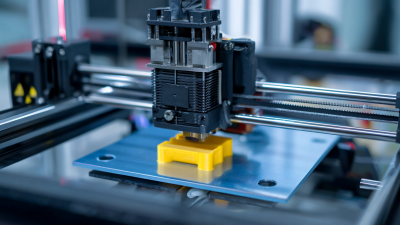

The advancements in speed and efficiency of 3D printing technologies are set to revolutionize the manufacturing landscape by 2025. According to a report by Wohlers Associates, the global 3D printing industry is projected to reach $35 billion by 2025, driven largely by innovations that enhance production rates. Emerging technologies, such as Continuous Liquid Interface Production (CLIP) and Multi Jet Fusion (MJF), have demonstrated speeds up to 100 times faster than traditional additive manufacturing methods. These advancements allow for rapid prototyping and on-demand production, significantly reducing lead times and operational costs.

Furthermore, the integration of artificial intelligence and machine learning into 3D printing processes is enhancing operational efficiency. A study from Gartner indicates that by 2025, more than 50% of organizations will deploy AI-based optimization tools that streamline printing workflows and reduce material waste. These technologies allow for predictive maintenance and real-time monitoring, ensuring that machines operate at peak efficiency. As companies seek to maximize productivity and sustainability, the combination of increased printing speeds and enhanced efficiency stands to redefine how products are designed and manufactured across various industries.

The integration of AI and machine learning within 3D printing processes is poised to redefine the industry by 2025. With the global 3D printing market projected to reach $34.8 billion by 2025, incorporating advanced technologies like AI has become essential for optimizing production efficiency and enhancing design capabilities. According to a report from Market Research Future, the use of AI can significantly reduce errors in the printing process, leading to cost savings of up to 30% by minimizing material waste and improving print accuracy.

AI algorithms enable 3D printers to analyze and learn from previous print jobs, automatically adjusting parameters in real-time for optimal results. This adaptability not only enhances the quality of the output but also accelerates the development cycle of new products. For instance, a study by Gartner highlights that 65% of enterprises implementing AI-enhanced 3D printing experienced shortened time-to-market for new designs. Additionally, predictive maintenance powered by machine learning helps in foreseeing equipment failures, which can cut unexpected downtimes by nearly 25%, further streamlining production workflows.

As we look towards 2025, the convergence of AI and 3D printing technology will unlock unprecedented possibilities, allowing for more complex geometries and rapid prototyping. The synergy between these technologies will not only elevate product innovation but will also ensure that industries can meet the growing demand for personalized and sustainable manufacturing solutions.

| Trend | Description | Impact on Industry | Expected Growth (%) |

|---|---|---|---|

| AI-Driven Design Optimization | Utilizing AI algorithms to enhance design efficiency and reduce material wastage. | Increased design innovation and cost efficiency. | 25% |

| Automation in 3D Printing | Integration of automated systems to streamline the printing process. | Reduction in manual labor and improved production speeds. | 30% |

| Sustainability Focus | Development of eco-friendly materials and processes in 3D printing. | Enhanced public perception and compliance with regulations. | 40% |

| Smart Factories | Implementation of IoT for real-time monitoring and data analysis. | Improved efficiency and reduced downtime. | 35% |

| Personalization and Customization | Use of AI to enable mass customization of products to meet individual needs. | Increased customer satisfaction and market competitiveness. | 28% |

As we look forward to 2025, sustainability will play a pivotal role in shaping the future of 3D printing technology. One of the key trends will be the increased use of bio-based and recycled materials. Manufacturers are actively working towards developing filaments derived from renewable sources that not only reduce carbon footprints but also minimize waste. This shift from conventional plastics to more sustainable alternatives aligns with the global push for eco-friendly practices across all industries.

Another significant trend will be the implementation of energy-efficient printing processes. Innovations in printer technology, such as enhanced thermal management and energy recovery systems, will reduce the energy consumption associated with 3D printing. In addition, companies are likely to adopt more efficient workflows that limit material waste, such as optimized design techniques that ensure each print utilizes as little material as possible while still meeting quality standards. By prioritizing these eco-friendly practices, the 3D printing industry can greatly contribute to a more sustainable manufacturing landscape.

The growing applications of 3D printing technology across various industries are transforming traditional manufacturing methods, promoting efficiency, customization, and sustainability.

In healthcare, for instance, 3D printing facilitates the production of custom prosthetics and dental implants tailored to individual patient specifications.

This level of personalization not only enhances patient comfort but also speeds up recovery times, as these bespoke solutions can be created quickly and accurately.

In healthcare, for instance, 3D printing facilitates the production of custom prosthetics and dental implants tailored to individual patient specifications.

This level of personalization not only enhances patient comfort but also speeds up recovery times, as these bespoke solutions can be created quickly and accurately.

Additionally, the automotive and aerospace sectors are leveraging 3D printing for rapid prototyping and the production of lightweight components.

By utilizing advanced materials, manufacturers can reduce vehicle weight without compromising structural integrity, leading to improved fuel efficiency and reduced emissions.

Moreover, construction industries are beginning to adopt large-scale 3D printing techniques for building structures, which significantly cuts down construction time and labor costs.

These diverse applications underline the considerable impact of 3D printing technology, reflecting its potential to revolutionize manufacturing and design across all sectors by 2025.

Moreover, construction industries are beginning to adopt large-scale 3D printing techniques for building structures, which significantly cuts down construction time and labor costs.

These diverse applications underline the considerable impact of 3D printing technology, reflecting its potential to revolutionize manufacturing and design across all sectors by 2025.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |