The 138th China Import and Export Fair, set to take place in 2025, presents a significant platform for innovations in various sectors, particularly in the realm of manufacturing. Among the highlights of this year's event is the exploration of rapid prototyping sheet metal technologies, which are transforming how industries approach product design and fabrication. Rapid prototyping sheet metal allows manufacturers to develop high-quality prototypes in a fraction of the traditional time, fostering greater efficiency and enhanced creativity. This innovation not only streamlines the production process but also supports rapid iterations, enabling companies to respond quickly to market demands and customize products with precision. As exhibitors showcase their advancements in this field, the fair serves as an essential gathering for professionals seeking to stay at the forefront of technological trends and collaborate on the future of sheet metal manufacturing.

Rapid prototyping is revolutionizing sheet metal fabrication by significantly reducing the time and cost associated with developing new designs. The ability to quickly create prototypes allows manufacturers to test and refine their concepts before committing to full-scale production. This iterative process not only enhances design precision but also fosters innovation as engineers can experiment with various geometries and materials without the fear of waste or excessive expenditure.

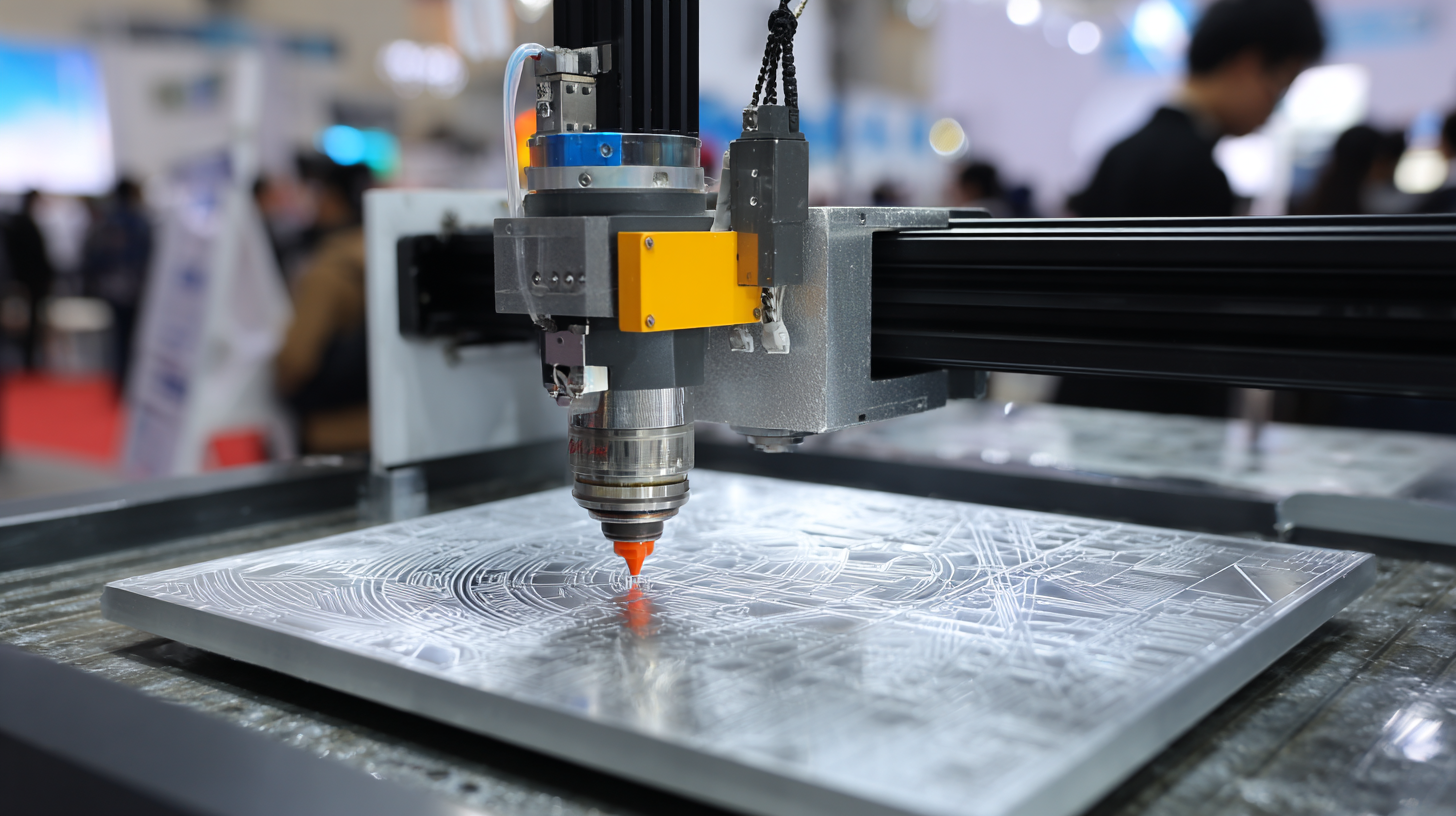

At the 138th China Import and Export Fair 2025, the emphasis on rapid prototyping technologies showcases their critical role in advancing the sheet metal industry. As manufacturers strive to meet increasingly complex market demands, rapid prototyping facilitates a more agile response to customer needs. The integration of advanced technologies, such as 3D printing and laser cutting, into the prototyping phase enables unprecedented flexibility and efficiency in the manufacturing process, ultimately leading to higher quality products and shorter lead times.

| Innovation Type | Description | Benefits | Application Areas | Year of Introduction |

|---|---|---|---|---|

| Laser Cutting Technology | Utilizes laser beams to cut sheet metal with high precision. | Increased accuracy and reduced waste material. | Automotive, Aerospace, Electronics | 2018 |

| 3D Printing Integration | Combines traditional sheet metal fabricating techniques with 3D printing. | Faster production times and complex geometries. | Prototype Development, Custom Parts | 2021 |

| CNC Machine Automation | Automated CNC machines for higher throughput and consistency. | Reduced human error and improved efficiency. | Mass Production, Heavy Equipment | 2019 |

| Rapid Tooling Techniques | Utilizes additive manufacturing to create tooling quickly. | Decreased lead times for tooling setups. | Short Run Production, Quick Prototyping | 2020 |

At the 138th China Import and Export Fair 2025, a plethora of advancements in sheet metal prototyping technologies have garnered significant attention from industry professionals. Innovations such as automated laser cutting and 3D printing integration have streamlined the prototyping process, allowing for faster turnaround times and enhanced customization. These technologies enable manufacturers to produce complex geometries with precision, reducing material waste and minimizing production costs.

Furthermore, the introduction of smart software solutions that utilize artificial intelligence is revolutionizing the prototyping landscape. These tools facilitate real-time adjustments and simulations, empowering designers to iterate rapidly and efficiently. Attendees at the fair witnessed live demonstrations of these innovations, showcasing how they can transform traditional manufacturing approaches into smart, agile processes capable of meeting the demands of contemporary markets. The event not only highlighted current breakthroughs but also inspired conversations around the future of sheet metal prototyping, promising a shift toward more sustainable and efficient manufacturing practices.

The rapid prototyping sector in China's manufacturing landscape is witnessing significant advancements, empowered by technological innovations and an increasing demand for efficiency. According to industry forecasts, the global Computer-Aided Engineering (CAE) market is projected to reach a staggering value of $7.072 billion by 2025, with a Compounded Annual Growth Rate (CAGR) of 7.9%, climbing further to $12.993 billion by 2033. This growth trajectory underscores the rising integration of rapid prototyping technologies across various manufacturing processes.

Moreover, the jewelry crafting and precious metal processing equipment market is set to grow considerably, with an estimated market size of $1.5 billion in 2024. This sector is expected to expand at a CAGR of 6.3% from 2025 to 2034, driven primarily by the increasing adoption of automation and digital design tools. These trends reflect a broader movement towards enhanced production capabilities, positioning China as a key player in the realm of rapid prototyping and innovative manufacturing solutions.

The rapid prototyping of sheet metal has gained remarkable traction within the manufacturing sector, notably showcased at the 138th China Import and Export Fair in 2025. Case studies reveal that early adopters of rapid prototyping technologies are achieving significant efficiency and accuracy improvements in production processes. According to a recent report by MarketsandMarkets, the global market for rapid prototyping in manufacturing is projected to reach $2.4 billion by 2026, with a compound annual growth rate (CAGR) of 25.32% from 2021 to 2026. This growth is driven by the increasing demand for customized metal components and the need for faster turnaround times.

In the sheet metal industry, companies such as XYZ Industries have successfully implemented rapid prototyping to streamline their design and production workflows. By leveraging advanced technologies like 3D printing and CNC machining, they have reduced lead times by up to 40%, allowing for quicker response to market demands. Furthermore, a case study in a recent engineering journal highlighted that using rapid prototyping resulted in a 30% reduction in material waste, translating into significant cost savings and a lower environmental impact. These successes underline the vital role that rapid prototyping plays in modernizing sheet metal fabrication and enhancing competitiveness in a rapidly evolving industry.

At the 138th China Import and Export Fair 2025, the advancements in rapid prototyping within the sheet metal industry will be a significant focus, particularly concerning sustainability and efficiency. Rapid prototyping technologies, such as 3D printing and CNC machining, offer companies a revolutionary way to minimize material waste. According to a report by Smithers, the adoption of rapid prototyping can reduce waste by up to 30% in the manufacturing process. This not only enhances resource efficiency but also aligns with global sustainability goals by decreasing the environmental impact associated with excess material usage.

Moreover, the shift toward rapid prototyping in sheet metal fabrication is transforming traditional manufacturing practices. The National Institute of Standards and Technology (NIST) notes that rapid prototyping can cut down production time by up to 50%, allowing for quicker iterations and the ability to pivot designs with minimal cost implications. This efficiency, combined with reduced waste, makes rapid prototyping an enticing option for manufacturers who are increasingly held accountable for their ecological footprint. As the industry moves towards more sustainable practices, the innovations showcased at this year’s fair will likely set the standard for future developments in sheet metal prototyping and production.

This chart illustrates the reduction in material waste percentage achieved through various rapid prototyping techniques over the years. The data showcases significant advancements in sustainability within the manufacturing sector.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |