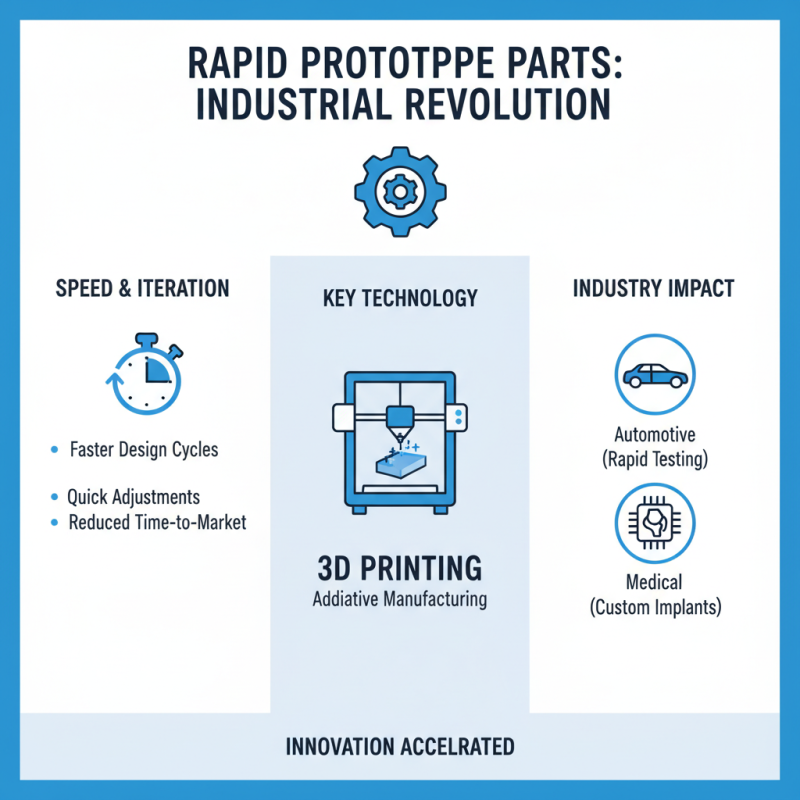

In today’s manufacturing landscape, rapid prototype parts are crucial for innovation and efficiency. According to a recent report by the Society of Manufacturing Engineers, approximately 70% of companies now prioritize rapid prototyping in their product development processes. This shift underscores the increasing reliance on quick turnaround times and the ability to test designs before full production.

Expert John Simmons, a lead engineer at Prototyping Solutions, emphasizes the importance of this technology. He states, “Rapid prototype parts revolutionize how we approach design challenges.” This sentiment highlights how vital these components are in reducing time-to-market and facilitating iterative design methods.

Despite their advantages, challenges remain. Many teams struggle with integrating rapid prototyping into established workflows. There is often a learning curve that can slow initial adoption. Acknowledging these hurdles is essential for companies aiming to fully leverage the benefits of rapid prototype parts.

Rapid prototyping plays a crucial role in modern manufacturing. It allows companies to develop and test parts quickly. By creating prototypes, designers can visualize their ideas. This process encourages innovation and reduces time spent on product development. However, rapid prototyping has its challenges. If not executed well, it can lead to misaligned expectations.

The purpose of rapid prototyping is to refine designs before full-scale production. Manufacturers can identify issues early, saving time and money. Detailed prototypes help teams focus on functionality and design. However, the materials used can affect the prototype's quality. Sometimes, the final product only reveals problems during production.

By embracing rapid prototyping, companies can stay competitive. The ability to adapt and improve designs quickly is a key advantage. But maintaining quality while speeding up the process is essential. It requires constant reflection and adjustment to ensure successful outcomes.

Rapid prototype parts have transformed product development. These parts allow designers to test ideas early in the process. By creating physical models quickly, teams can identify flaws sooner. This speeds up the iteration phase. It also reduces the cost of late-stage changes. Rapid prototypes serve as a tangible representation of concepts. They provide insights that digital models simply can't.

One significant benefit is user feedback. Teams can present prototypes to potential users for real-time reactions. This feedback can inspire adjustments that enhance functionality. However, relying too heavily on prototypes can lead to misinterpreting user needs. It's vital to balance prototype testing with thorough market research.

Rapid prototyping also shortens the time to market. Businesses that utilize these parts gain a competitive edge. But rushing the process may compromise quality. Some prototypes may not meet all specifications. Continuous reflection on design and functionality is crucial. The iterative nature of prototyping encourages learning from mistakes. Ultimately, rapid prototypes create opportunities for innovation while presenting challenges.

Rapid prototyping has transformed manufacturing. It accelerates the development of products. Companies can create parts quickly. This speed reduces time-to-market significantly. Designers can test ideas faster. Mistakes are identified early. This leads to better final products.

Tip: Use CAD software to streamline your designs before prototyping. It saves time and reduces errors.

With rapid prototyping, iteration becomes easy. Teams can make alterations based on feedback. They revisit designs often. However, it’s worth noting that not all prototypes will hit the mark. There can be unexpected challenges. Each iteration teaches valuable lessons.

Tip: Embrace failure as part of the process. Analyzing what went wrong can lead to innovation.

The role of rapid prototyping is vital. It narrows the gap between concept and production. Faster cycles lead to improved market responsiveness. This efficiency offers a competitive edge. Adopting this practice is a step toward modern manufacturing success. Balancing speed and quality remains crucial.

This chart illustrates the average time-to-market for products developed using traditional manufacturing methods compared to rapid prototyping. As shown, rapid prototyping significantly reduces the time required to bring a product from concept to market, emphasizing its essential role in modern manufacturing.

Traditional prototyping often requires extensive time and resources. Engineers create models using methods like CNC machining or hand crafting. This process can lead to delays. It feels slow, frustratingly so. A single mistake can derail an entire project. The costs pile up quickly if changes are needed.

Rapid prototyping emerges as a solution. This technique allows for quick iterations. 3D printing and additive manufacturing enable faster production. Designers can create parts in hours, not weeks. It allows teams to test ideas and make adjustments on the fly. Prototyping becomes a more fluid process. Mistakes happen, but they happen faster. Teams learn quickly from those errors.

Tips: Always gather feedback early. It reduces the risk of costly mistakes later. Keep communication open with all team members. This creates a collaborative environment. Embrace the imperfections; they offer valuable lessons. They reveal what works and what doesn't. Rapid prototyping encourages a culture of experimentation, where learning is part of the journey.

Rapid prototype parts are revolutionizing industries. Many sectors now embrace these components for product development. For example, the automotive industry relies on rapid prototyping to test designs quickly. Engineers create parts using 3D printing technology, which allows for rapid adjustments. This can significantly reduce the time taken to bring a car from concept to market.

The healthcare sector also benefits from rapid prototyping. Medical devices require precision and reliability. Prototyping enables manufacturers to create custom devices tailored to individual patient needs. These prototypes can undergo rigorous testing, leading to better designs. However, the process is not without challenges. Iterative testing can be costly and time-consuming. Manufacturers must balance speed with quality, re-evaluating their methods continuously. Real-world testing sometimes reveals flaws that were not apparent during the design phase. This requires teams to be adaptable and ready to refine their prototypes based on feedback.

Once overlooked, rapid prototype parts have now become essential. Industries that adopt this approach often find it leads to innovation. Challenges remain, yet the journey of improvement is part of the process. Many companies are not yet fully equipped to handle rapid changes, leading to missed opportunities. Companies need to embrace this method to stay competitive in an evolving market. The transformation is ongoing, with lessons learned daily.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |