In the rapidly evolving landscape of modern manufacturing, "rapid prototype machining" has emerged as a pivotal technology driving innovation and efficiency. According to a report by Grand View Research, the global rapid prototyping market is expected to reach USD 23.9 billion by 2025, growing at a CAGR of 29.2%. This surge is fueled by the increasing demand for custom part production and the need for faster product development cycles.

As industries ranging from aerospace to automotive leverage rapid prototype machining for its ability to produce complex geometries with precision, manufacturers are now able to iterate designs quickly, minimize waste, and significantly reduce lead times. The continuous advancements in machining technologies further enhance capabilities, enabling the production of high-quality prototypes that meet stringent industry standards. Understanding these trends is essential for stakeholders aiming to stay competitive in this dynamic environment.

In the rapidly evolving landscape of modern manufacturing, "rapid prototype machining" has emerged as a pivotal technology driving innovation and efficiency. According to a report by Grand View Research, the global rapid prototyping market is expected to reach USD 23.9 billion by 2025, growing at a CAGR of 29.2%. This surge is fueled by the increasing demand for custom part production and the need for faster product development cycles.

As industries ranging from aerospace to automotive leverage rapid prototype machining for its ability to produce complex geometries with precision, manufacturers are now able to iterate designs quickly, minimize waste, and significantly reduce lead times. The continuous advancements in machining technologies further enhance capabilities, enabling the production of high-quality prototypes that meet stringent industry standards. Understanding these trends is essential for stakeholders aiming to stay competitive in this dynamic environment.

Rapid prototype machining is experiencing a revolutionary transformation driven by advanced technologies that improve efficiency and effectiveness in manufacturing. Key innovations such as automation and digital manufacturing are reshaping processes across multiple industries. A systematic review analyzing 53 articles emphasizes the crucial role of automation technologies in the manufacturing and assembly stages, enhancing productivity and reducing lead times. As manufacturers integrate these technologies, they witness a significant acceleration in production capabilities, evidenced by the latest growth projections for the CNC machine market, anticipating substantial size increases by 2032.

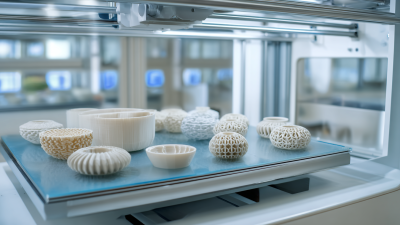

Moreover, the advent of laser microfabrication techniques is propelling rapid prototyping into the mainstream, allowing manufacturers to create intricate three-dimensional structures through additive manufacturing. As highlighted in recent insights from influential executives in the 3D printing industry, the trend towards adopting digital manufacturing has resulted in improved product stability and resilience, exemplified by successful prototypes developed for high-demand applications. By bridging the gap between prototypes and full-scale production, companies are not only diversifying their manufacturing processes but also ensuring they remain competitive in an ever-evolving marketplace.

| Technology Type | Adoption Rate (%) | Key Benefits | Industry Application |

|---|---|---|---|

| 3D Printing | 65 | Rapid design iteration, cost-effectiveness | Aerospace, Automotive |

| CNC Machining | 80 | High precision, material versatility | Medical Devices, Consumer Electronics |

| Laser Cutting | 70 | Clean cuts, no material waste | Architecture, Signage |

| Injection Molding | 75 | Mass production, high tolerance | Consumer Products, Toys |

| Metal Additive Manufacturing | 60 | Complex geometries, lightweight structures | Aerospace, Defense |

The manufacturing landscape is rapidly evolving, driven by key trends in rapid prototype machining and its integration with advanced technologies. According to recent reports, the CNC machine market is projected to grow from $101.22 billion in 2025 to an estimated $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This growth is fueled by increasing demand for automation and precision in manufacturing processes, as businesses seek to enhance efficiency and reduce production times.

Moreover, the simulation software market is experiencing significant expansion, with projections indicating growth from $15.00 billion in 2025 to $33.62 billion by 2032, at a CAGR of 12.2%. This trend emphasizes the crucial role of simulation tools in optimizing designs and prototyping workflows, enabling manufacturers to innovate swiftly and reduce time-to-market. As these technologies continue to develop, they are reshaping traditional manufacturing paradigms, pushing companies towards more agile production strategies that emphasize rapid prototyping and the effective utilization of resources.

The impact of additive manufacturing on traditional prototype machining techniques has become increasingly significant as the industry shifts towards more innovative and efficient production methods. According to a report by Wohlers Associates, the global additive manufacturing market is expected to reach $41 billion by 2026, reflecting a compounded annual growth rate (CAGR) of 25.76% from 2021. This growth is driving manufacturers to integrate additive processes, such as 3D printing, to complement conventional machining techniques in prototype development.

Traditional machining methods, characterized by subtractive techniques, have often faced limitations in terms of design flexibility and lead times. However, the incorporation of additive manufacturing enables designers to create complex geometries that would be challenging or impossible to achieve through machining alone. Data from the McKinsey Global Institute indicates that companies leveraging these hybrid approaches could reduce product development time by up to 75%, thereby enhancing their competitive advantage. As industries embrace these technologies, the synergy between additive and traditional machining is set to redefine prototype creation, optimizing performance and reducing material waste in the manufacturing landscape.

In the era of advanced manufacturing, data-driven decision-making has emerged as a pivotal approach for enhancing rapid prototype machining. By leveraging analytics, companies can gain valuable insights into their machining processes, leading to more efficient operations and improved product quality. The integration of real-time data collection, monitoring systems, and advanced analytics allows manufacturers to identify bottlenecks and inefficiencies within their workflows. This proactive approach not only reduces production time but also minimizes resource wastage, aligning with the modern industry's push for sustainability.

Moreover, predictive analytics is revolutionizing how manufacturers anticipate potential issues before they impact production. By analyzing historical data, organizations can forecast machine failures, optimize maintenance schedules, and refine machining parameters for better outcomes. The use of machine learning algorithms provides an added layer of intelligence, enabling systems to adapt and learn from previous cycles. As a result, businesses can not only enhance their prototype machining processes but also foster a culture of continuous improvement, driving innovation in the manufacturing sector.

The landscape of manufacturing has been transformed by the rapid prototyping techniques adopted across various industries. For instance, in the automotive sector, companies have leveraged rapid prototyping for sustainable design. The iterative process of creating prototypes allows for quick adjustments and a faster route to market, significantly reducing the time needed for product development. This adaptability has empowered manufacturers to experiment with innovative designs while minimizing waste.

In the aerospace industry, rapid prototyping has led to remarkable improvements in efficiency and safety. By creating lightweight components using 3D printing technologies, companies can push boundaries in aircraft design. Successful case studies illustrate how prototypes are tested and refined, leading to superior performance and compliance with stringent industry regulations.

Tips: When implementing rapid prototyping, prioritize collaboration among engineering teams. Establishing clear communication channels can streamline the feedback loop, allowing for quicker revisions and enhancing the overall development process. Additionally, invest in advanced software tools that facilitate real-time simulations to anticipate potential challenges early on, ensuring a smoother transition from prototype to production.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |