Quick turn injection molding is an innovative manufacturing process that has gained significant traction in various industries, owing to its ability to produce high-quality plastic components rapidly and efficiently. This method is especially beneficial for applications that require quick prototyping and low-volume production, allowing designers and engineers to accelerate the product development cycle. The significance of quick turn injection molding lies in its capacity to adapt to market demands swiftly, offering a cost-effective solution while maintaining precision and accuracy in component design.

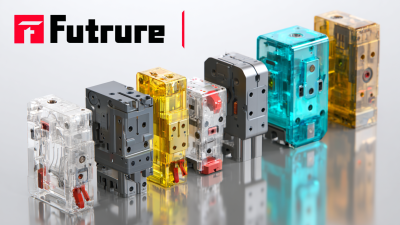

The process itself involves the use of specialized equipment and techniques that facilitate rapid tooling and quick part fabrication. This enables manufacturers to reduce lead times significantly, meeting tight project timelines without compromising on quality. Moreover, quick turn injection molding opens doors to a myriad of applications, from automotive and consumer goods to medical devices and electronics. As industries continue to evolve, the need for speed and flexibility in production has never been more critical, making quick turn injection molding a pivotal player in modern manufacturing strategies.

In this exploration of quick turn injection molding, we will delve into its benefits, the intricacies of the process, and the diverse applications it serves across multiple sectors. By understanding the fundamentals and advantages of this methodology, businesses can leverage quick turn injection molding to enhance their production capabilities and stay competitive in an ever-changing marketplace.

Quick turn injection molding has emerged as a game-changer in the manufacturing landscape, offering significant advantages that cater to the demand for speed and efficiency. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $380 billion by 2025, with a notable shift towards rapid production techniques.

Quick turn injection molding minimizes lead time from design to production, enabling manufacturers to respond swiftly to market changes and customer demands. This agility allows companies to produce parts in as little as a few days, a stark contrast to traditional methods that can take weeks or even months.

Moreover, the cost-efficiency of quick turn injection molding cannot be overlooked. Industry studies indicate that rapid prototyping and production can reduce total manufacturing costs by up to 20-30% compared to conventional processes. By utilizing advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM), manufacturers can produce highly precise molds that lead to reduced waste and shorter production cycles. Additionally, the flexibility to create small production runs with the same efficiency as larger batches means that companies can innovate without the financial burden of large stock inventories, ultimately enabling a smoother path to market for new products.

Quick turn injection molding (QTIM) is a specialized manufacturing process that enables rapid production of plastic parts. The mechanics of this process involve several critical stages that work in concert to streamline production timelines. Initially, a mold is created using advanced techniques like computer-aided design (CAD) and computer-aided manufacturing (CAM). This precision guarantees that the resulting mold reflects the intended product design, making the initial setup time efficient. Once the mold is prepared, the injection phase involves melting plastic pellets and injecting them under high pressure into the mold cavity, facilitating rapid cooling and solidification.

The speed of the quick turn injection molding process lies not only in the efficiency of the manufacturing setup but also in the use of advanced materials and cutting-edge machinery. The entire operation can often be completed within days instead of weeks, allowing for shorter lead times. Additionally, the flexibility of QTIM enables manufacturers to produce low to medium volume parts with high precision, catering to diverse industries from automotive to consumer goods. As a result, understanding the intricate mechanics behind QTIM sheds light on its growing popularity as an essential tool for rapid prototyping and production.

| Aspect | Description |

|---|---|

| Speed | Quick turn injection molding significantly reduces production time compared to traditional methods. |

| Cost Efficiency | Lower tooling costs and reduced lead times contribute to overall cost savings. |

| Material Versatility | Supports a wide range of materials, including thermoplastics and elastomers. |

| Customization | Allows for rapid prototyping and customization of parts to meet specific requirements. |

| Applications | Widely used in automotive, medical, consumer products, and electronics industries. |

| Process Overview | Involves rapid designing, prototyping, and production in a single workflow. |

Quick Turn Injection Molding (QTIM) is revolutionizing production across several key industries due to its ability to reduce lead time and costs while maintaining high-quality output. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach $335 billion by 2027, driven largely by advancements such as QTIM. This process is particularly beneficial in sectors that require rapid prototyping and small batch production, such as consumer goods, automotive, and medical devices. These industries are increasingly adopting QTIM to meet the growing demand for customized and quick-turnaround solutions without compromising on precision.

In the automotive sector, for example, manufacturers are leveraging QTIM to produce components more swiftly, allowing them to adapt to market changes and consumer preferences in real-time. A report from the Society of Automotive Engineers highlights that reducing time to market can enhance competitiveness, making QTIM an attractive option for producing everything from dashboard elements to intricate connectors. Similarly, in the medical device industry, where regulatory compliance and rapid innovation are crucial, QTIM is being utilized to create prototypes and production parts quickly, thus ensuring that companies can expedite product testing and launch cycles. This shift towards QTIM is not only about efficiency but also enhances the ability to innovate and tailor solutions to meet specific customer needs, which is increasingly important in today's fast-paced market environment.

Quick turn injection molding has emerged as a pivotal solution for industries looking to enhance their production capabilities while maintaining cost efficiency. Recent studies indicate that companies utilizing quick turn injection molding can reduce product development time by up to 50%, enabling them to respond swiftly to market demands. The process allows for rapid prototyping and small-batch production, which significantly minimizes upfront costs compared to traditional injection molding methods. For instance, a report from the Plastics Industry Association highlights that nearly 70% of businesses leveraging quick turn solutions experience a marked increase in their market agility and overall profitability.

In terms of cost savings, quick turn injection molding offers reduced overhead expenses through its streamlined manufacturing process. By eliminating the lengthy setup times associated with conventional molding, manufacturers can produce high-quality parts with lower labor costs and minimized waste. According to a survey conducted by the Society of Plastics Engineers, firms adopting this technology report a decrease in per-unit production costs by as much as 30%. This cost-effectiveness, combined with a quicker route to market, positions quick turn injection molding as a favorable option for industries ranging from automotive to consumer electronics, ultimately driving innovation and competitiveness in a rapidly evolving marketplace.

The landscape of quick turn injection molding is rapidly evolving, driven by advancements in technology and increasing demand for faster production cycles. One of the most significant trends is the integration of automation and artificial intelligence into the molding process. These innovations streamline operations, reducing the time from design to finished product and enhancing precision in manufacturing. Companies are increasingly investing in smart molds equipped with sensors to monitor conditions in real time, ensuring consistent quality and minimizing waste.

Another noteworthy development is the rise of sustainable materials within quick turn injection molding. As environmental concerns become more critical, the industry is shifting towards biodegradable and recyclable plastics. This not only reduces the carbon footprint but also meets the growing consumer demand for eco-friendly products. Moreover, advancements in material science are paving the way for new composites that are lighter and stronger, further expanding the applications of quick turn injection molding across various sectors.

**Tips:** When exploring quick turn injection molding options, consider the latest technologies that enhance efficiency, such as 3D printing for mold design. Additionally, keep an eye on emerging materials that offer both sustainability and performance, as these will be crucial for competitive advantage in the market. Lastly, regular training for your team on these innovative processes can significantly impact the overall success and adaptability of your production capabilities.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |