In the rapidly evolving landscape of product development, the significance of prototype parts cannot be overstated. According to a report by Deloitte, nearly 70% of product failures can be attributed to inadequate prototyping practices, underscoring the crucial role that prototype parts play in validating concepts and refining designs. These components allow teams to test functionality, assess materials, and explore manufacturability before committing to full-scale production, ultimately saving time and reducing costs.

Moreover, a study from the Product Development and Management Association highlights that organizations that effectively utilize prototype parts in their development processes enjoy a 25% faster time-to-market than those that do not. This is particularly important in industries where innovation cycles are short, and consumer expectations are ever-increasing. The ability to iterate rapidly using prototype parts ensures that companies remain competitive and responsive to market demands, setting the stage for successful product launches and customer satisfaction. As such, acknowledging the value of prototype parts is essential for businesses aiming to thrive in today's dynamic environment.

In product development, prototype parts are the preliminary components created to test and validate design concepts before full-scale production. These parts serve as a tangible representation of the final product, allowing designers and engineers to evaluate functionality, usability, and manufacturability. According to a report by the Product Development and Management Association (PDMA), companies that effectively utilize prototyping in their development process can reduce time-to-market by up to 30%, leading to quicker innovation cycles and increased competitiveness.

Prototyping also plays a crucial role in identifying potential design flaws early in the process. A study by the National Institute of Standards and Technology (NIST) found that addressing issues during the prototyping phase can reduce product development costs by approximately 75% compared to making adjustments during production. By investing in quality prototype parts, companies can ensure their final products meet consumer needs and avoid costly revisions.

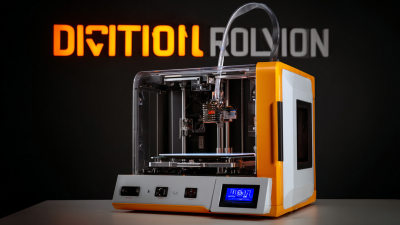

Tips: When creating prototype parts, consider employing advanced technologies like 3D printing, which can significantly speed up the prototyping process and offer cost-efficient solutions. Additionally, involving cross-functional teams early in the prototyping phase can provide diverse insights, enhancing the overall design and functionality of the product.

Prototype parts play a critical role in the realm of innovative design, functioning as tangible representations of concepts that are still in the development phase. These parts allow designers and engineers to explore their ideas, assess their feasibility, and make necessary iterations. By utilizing prototype parts, teams can identify potential flaws, test functionalities, and evaluate overall user experience before committing to full-scale production. This iterative process not only enhances the quality of the final product but also accelerates time-to-market, making it vital in today's fast-paced environment.

Moreover, prototype parts facilitate communication among stakeholders. Designers, engineers, and investors can use physical prototypes to convey ideas more effectively than through sketches or digital models alone. This clarity fosters collaboration and encourages constructive feedback, which can lead to improved designs and innovations. Ultimately, the use of prototype parts in innovative design processes is pivotal; it bridges the gap between abstract ideas and practical solutions, ensuring that products meet both user needs and market demands.

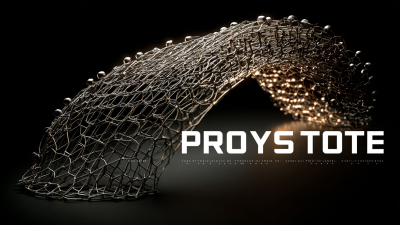

In product development, prototype parts serve as the tangible building blocks that allow designers and engineers to test concepts and refine their ideas. These parts often fall into several categories, each serving a distinct function. For instance, visual prototypes are primarily used for aesthetics and design validation, enabling teams to visualize the final product. Functional prototypes, on the other hand, focus on testing usability and performance, ensuring that the product operates as intended before mass production.

When working with prototype parts, it's essential to prioritize the type that aligns with your development goals. Tip: Always begin with low-fidelity prototypes to iterate quickly and gather initial feedback, which can save time and resources in the long run. Rapid prototypes, which can be created using 3D printing technologies, allow for fast adjustments based on user inputs, making them highly effective for early-stage testing.

Additionally, high-fidelity prototypes offer more advanced features and closely mimic the final product's functionality. Tip: Invest in user testing during this phase; observing real users interact with your high-fidelity prototypes can reveal invaluable insights that inform your design decisions. By understanding the specific roles of different prototype parts, teams can streamline their product development process and enhance their chances of success.

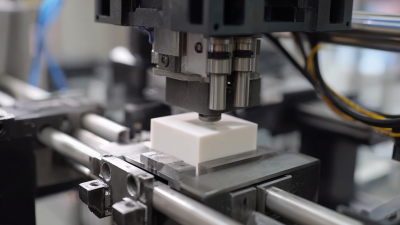

Creating effective prototype parts is a crucial step in product development, as it allows teams to visualize their ideas and test functionality before moving into full-scale production. The process typically begins with generating initial concepts, which are then translated into designs using CAD software. This step is crucial for identifying potential design flaws early on, saving both time and money.

After the design phase, the next step is selecting appropriate materials and manufacturing methods. The choice of materials can significantly impact the performance and cost of the prototype. 3D printing is a popular option due to its flexibility and speed, allowing rapid iteration on designs. To ensure a successful prototype, it's beneficial to involve interdisciplinary teams who can provide diverse perspectives and expertise.

Tips: When creating prototype parts, don’t hesitate to use feedback from potential users during the development process. Early engagement can reveal insights that might not have been considered otherwise. Additionally, keep your prototypes simple at first; complex features can come later once the core functionality has been validated. Lastly, maintain clear documentation throughout the prototyping process to track changes and improvements efficiently.

Prototype parts play a crucial role in product development, enabling designers and engineers to validate concepts and functionalities before full-scale production. However, the journey of utilizing prototype parts isn’t without challenges. According to a report by Deloitte, nearly 58% of product development teams experience delays due to issues related to prototypes, such as material choice and dimensional accuracy. These delays can substantially inflate project budgets and extend time-to-market, affecting competitiveness.

To navigate these challenges effectively, teams should prioritize clear communication and collaboration among stakeholders. Implementing iterative testing processes allows for feedback in real time, reducing costly iterations later in the development cycle. Additionally, investing in advanced prototyping technologies such as 3D printing can streamline the creation of parts, allowing for quicker adjustments and reduced reliance on traditional manufacturing lead times.

Tips: Consider employing virtual simulation tools to predict prototyping outcomes before physical development. Regularly review material performance data, which can guide the selection of the right components, enhancing both design integrity and functionality.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |