Plastic injection moulding is a pivotal manufacturing process that has significantly transformed the production of plastic components across various industries. According to a recent report by MarketsandMarkets, the global plastic injection moulding market is projected to reach over $370 billion by 2026, driven by the increasing demand for lightweight, durable, and cost-effective parts in sectors such as automotive, consumer goods, and electronics. As the process allows for rapid production and precision, many manufacturers are increasingly relying on it to achieve efficiency and scalability in their operations. This blog will delve into the intricate process behind plastic injection moulding, shedding light on its technological advancements, practical applications, and expert tips that can help optimize production while minimizing waste.

Plastic injection moulding is an essential manufacturing process that offers efficiency and precision in producing various plastic components. The key units of a standard injection moulding machine include the clamping device, the plasticizing device, and the drive unit, which together facilitate the creation of intricate designs while maintaining low production costs. According to industry reports, the demand for injection moulding is projected to grow significantly, driven by its ability to deliver high-volume production with minimal waste and energy consumption.

Recent advancements in this field include the development of bi-metal composite materials for tooling applications, utilizing fused filament fabrication (FFF) processes. This innovative technology allows for manufacturing injection moulding tooling with equipment that is three times less expensive than traditional methods, which can revolutionize cost structures in the industry. Moreover, new training programs aimed at closing the skills gap in plastic processing are emerging, ensuring the workforce is equipped with the necessary expertise to harness these advanced technologies effectively.

Research into optimizing the injection moulding process has also gained traction, with methodologies like soft computing and particle swarm optimization being employed to detect and rectify defects in plastic products, such as sink marks, shrinkage, and warpage. This focus on quality control emphasizes the importance of thorough process assessment to achieve high standards in plastic manufacturing, thereby meeting the evolving demands of various sectors.

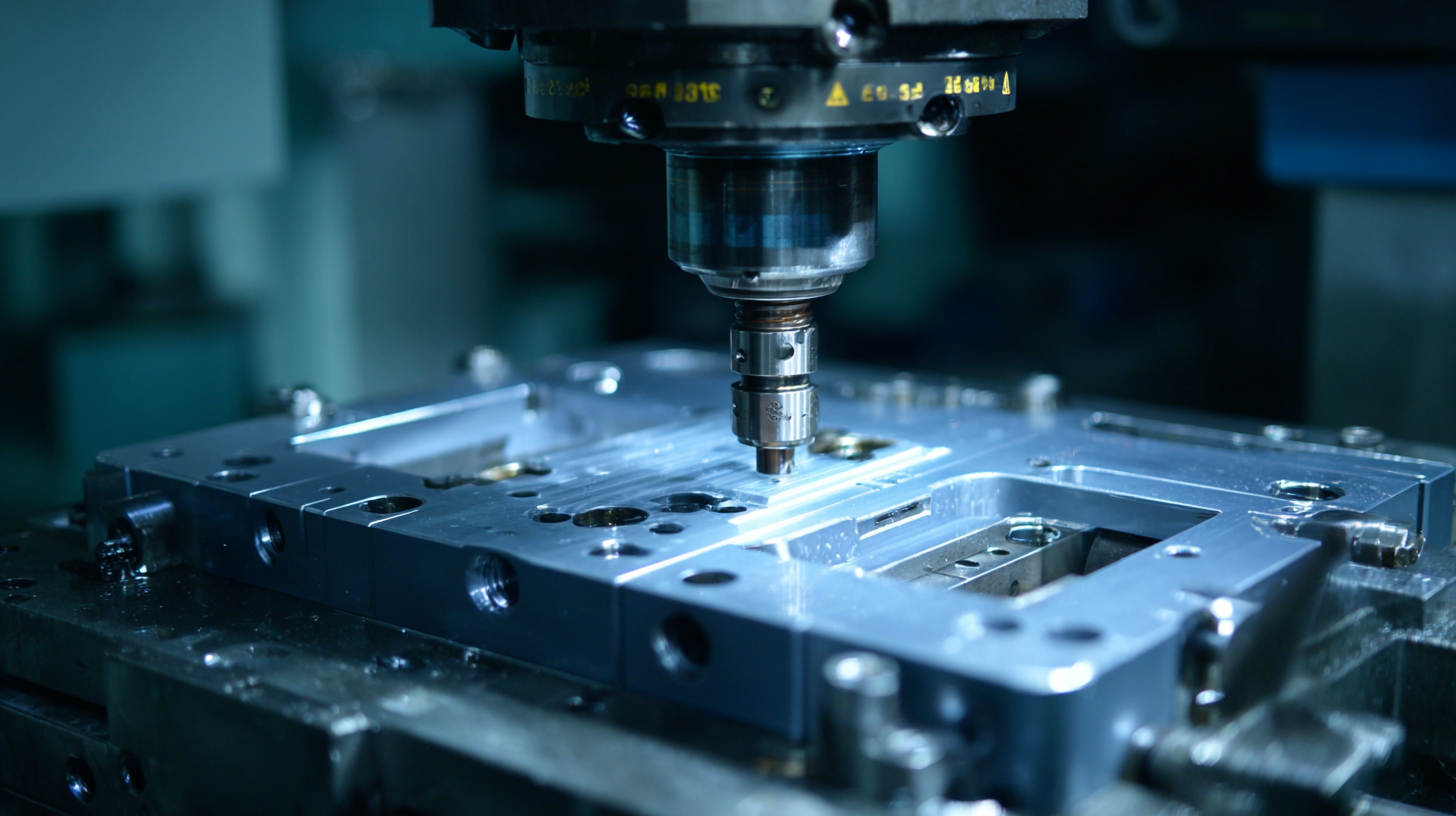

The plastic injection moulding process is a complex technique that involves several key components, each playing a crucial role in producing high-quality plastic products. The primary components include the injection unit, the moulding machine, and the cooling system. The injection unit is responsible for melting and injecting the plastic material into the mould, while the moulding machine provides the pressure required to shape the melted plastic. Lastly, the cooling system helps solidify the plastic, ensuring the final product maintains its intended shape and durability.

Tip: When engaging in plastic injection moulding, it's essential to consider the material selection carefully. Different types of plastics can behave differently during moulding, impacting the final product's strength and appearance. Always consult with material specialists to select the right plastic type for your specific application to optimize performance.

Tip: Another important aspect is the maintenance of the mould. Regular inspection and upkeep ensure that the mould remains in good condition, leading to better production outcomes. Implement a preventive maintenance schedule to address any wear and tear promptly, minimizing downtime and maximizing efficiency.

Injection moulding is a highly efficient and versatile manufacturing process widely used for producing a variety of polymer products. The process begins with the melting of plastic pellets, which are heated and fed into a reciprocating screw. This screw pushes the molten plastic into a pre-form cavity, where it takes the shape of the desired product. Once the mould is filled, the material cools and solidifies, allowing for the removal of the finished component from the mould.

Tips: When engaging in injection moulding, it's crucial to consider material selection carefully. Different polymers exhibit unique properties that can significantly affect the final product's performance. Additionally, maintaining optimal temperature control throughout the process can prevent defects and ensure product quality.

The cycle of injection moulding involves several key steps: clamping, injection, cooling, and ejection. Each phase is meticulously timed to guarantee efficiency and precision in production. Regularly reviewing and optimizing the mould design can also lead to improved cycle times and reduced operational costs, making the process more sustainable and cost-effective for manufacturers.

| Step | Description | Duration (seconds) | Energy Consumption (kWh) |

|---|---|---|---|

| 1. Material Preparation | Raw plastic pellets are dried and fed into the injection molding machine. | 10 | 0.005 |

| 2. Heating | Pellets are heated to a molten state in the barrel of the machine. | 20 | 0.02 |

| 3. Injection | Molten plastic is injected into the mold at high pressure. | 15 | 0.03 |

| 4. Cooling | The injected plastic cools and solidifies in the mold. | 30 | 0.01 |

| 5. Ejection | The final product is ejected from the mold. | 5 | 0.002 |

| 6. Trimming and Finishing | Excess material is trimmed and finishing processes are applied. | 25 | 0.015 |

Injection moulding is a versatile manufacturing process widely used across numerous industries, from automotive to consumer goods. In 2021, the global injection moulding market was valued at approximately $263 billion and is projected to reach about $365 billion by 2028, indicating a substantial growth trajectory (Grand View Research). This process is crucial in producing complex shapes that require high precision, which is why it is favored in industries that demand high-quality parts, such as the medical device sector, where stringent regulations govern product reliability and safety.

In the automotive industry, injection moulding plays a key role in creating lightweight parts that contribute to fuel efficiency and sustainability. For instance, more than 50% of all automotive Kunststoff components are produced using injection moulding techniques (Plastics News). Moreover, the packaging industry has embraced injection moulding to produce containers and caps, reflecting a shift towards more sustainable practices. The rising demand for eco-friendly packaging solutions has driven innovation in this sector, with many companies investing in bioplastic materials, thus further expanding the scope and applications of injection moulding across various industries.

In the automotive industry, injection moulding plays a key role in creating lightweight parts that contribute to fuel efficiency and sustainability. For instance, more than 50% of all automotive Kunststoff components are produced using injection moulding techniques (Plastics News). Moreover, the packaging industry has embraced injection moulding to produce containers and caps, reflecting a shift towards more sustainable practices. The rising demand for eco-friendly packaging solutions has driven innovation in this sector, with many companies investing in bioplastic materials, thus further expanding the scope and applications of injection moulding across various industries.

Plastic injection moulding is a widely adopted technique in the manufacturing industry, recognized for its efficiency and versatility. One of the primary advantages of this technology is its ability to produce complex and intricate shapes with high precision. The process involves injecting molten plastic into a mould, allowing for rapid production cycles and consistent quality across multiple units. This efficiency not only reduces costs but also meets the high demands of various industries, including automotive, consumer goods, and medical devices.

However, plastic injection moulding also comes with its challenges. One significant hurdle is the initial setup cost, which can be high due to the need for specialized machinery and custom moulds. Additionally, the process requires a thorough understanding of material properties and mould design to avoid defects such as warping or incomplete filling. Sustainability is another concern, as the environmental impact of plastic waste continues to rise. Manufacturers are increasingly exploring eco-friendly alternatives and recycling methods to mitigate this challenge, yet finding the balance between performance and sustainability remains a critical focus for the future of plastic injection moulding technology.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |