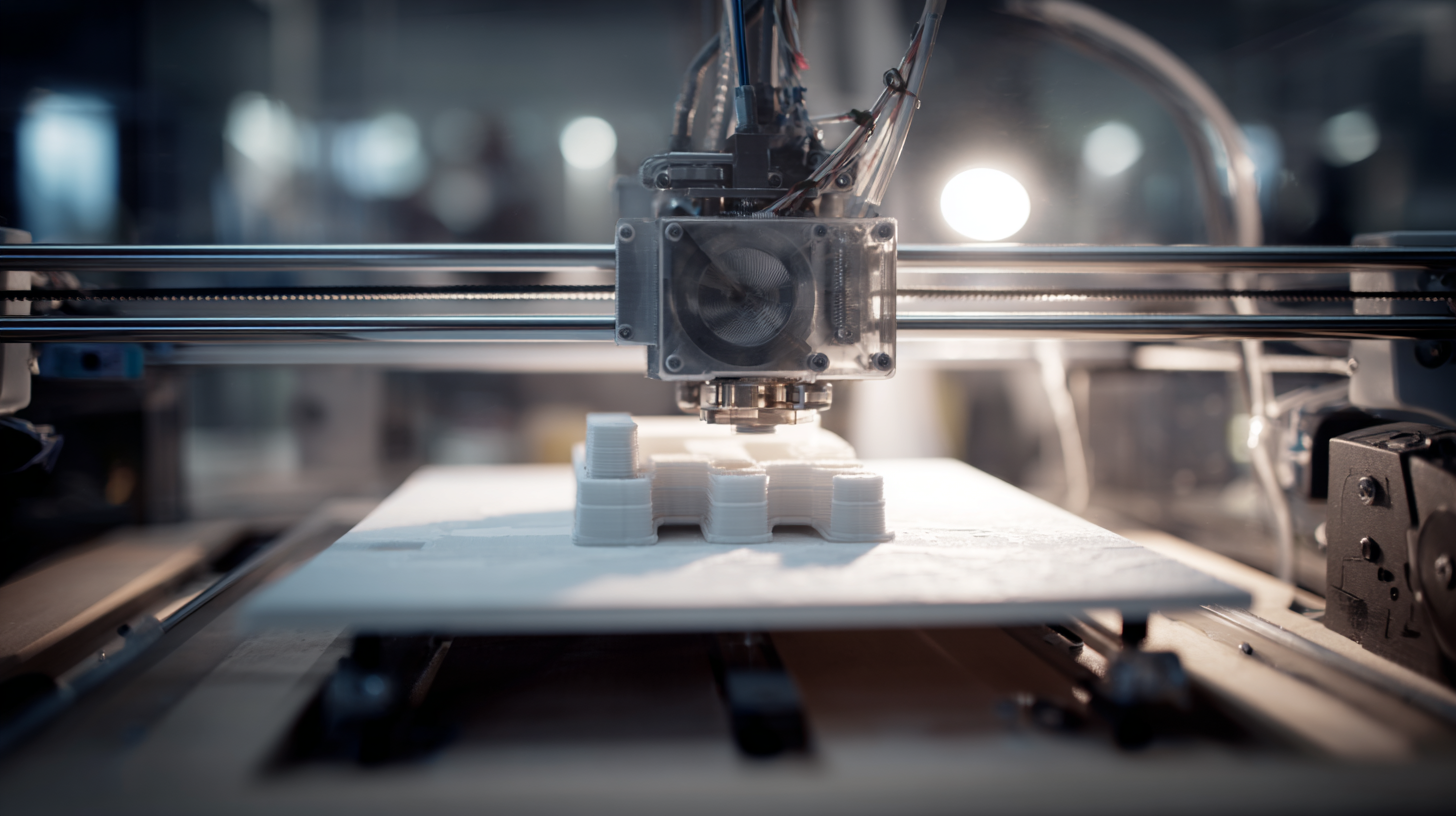

In today's fast-paced business environment, mastering 3D prototyping techniques has become essential for companies aiming to innovate and stay competitive. 3D prototyping allows businesses to create physical representations of their designs, enabling them to visualize concepts, conduct tests, and gather feedback before moving to full production. This iterative process not only accelerates product development but also minimizes risks associated with launching new products. By leveraging advanced 3D prototyping technologies, such as additive manufacturing and computer-aided design (CAD), businesses can enhance creativity, fine-tune functionalities, and achieve a higher level of customization. Understanding the various types of 3D prototyping is crucial for entrepreneurs who wish to harness these capabilities effectively and drive their business success. In this blog, we will explore different 3D prototyping techniques, their applications, and how they can be pivotal in transforming ideas into tangible realities.

Understanding the basics of 3D prototyping techniques is essential for businesses looking to innovate and streamline their production processes. At its core, 3D printing, or additive manufacturing, allows businesses to create physical objects layer by layer from digital models. This technology has revolutionized various industries, including automotive and healthcare, where rapid prototyping can lead to faster product development and customization. The flexibility of materials and the efficiency of the printing process are key advantages for companies seeking a competitive edge.

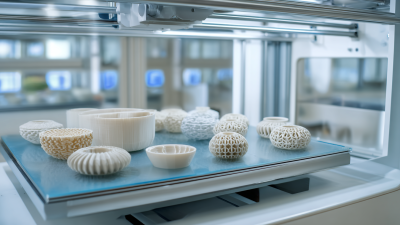

For businesses, mastering these 3D prototyping techniques can unlock new possibilities. The applications range from designing prototypes for consumer products to creating specialized components for machinery. As reported, the 3D printing industry continues to expand, with an increasing number of companies adopting this technology to improve their operational efficiency. With free online courses available, entrepreneurs and established businesses alike can enhance their skills and implement 3D printing in their strategies, fostering innovation and reducing costs in the long term.

When exploring different 3D prototyping technologies, it's essential to consider the specific needs of your business. Various methods, such as

Fused Deposition Modeling (FDM),

Stereolithography (SLA),

and Selective Laser Sintering (SLS), offer unique advantages that cater to different project requirements.

FDM is great for creating functional prototypes with durable materials, whereas SLA excels in producing highly detailed models with smooth finishes.

SLS, on the other hand, allows for more complex geometries and is ideal for small-batch production.

Tip 1: Assess your project's material requirements before selecting a technology.

If your prototype needs to endure physical stress or is intended for functional testing, prioritize

FDM or SLS.

For visual prototypes where aesthetics matter,

SLA would be your best choice.

Tip 2: Consider the scale of your production.

If you require rapid prototyping for small quantities,

SLA can provide faster turnaround times.

Conversely, if you're planning to produce larger runs or require structural integrity,

FDM or SLS may be more cost-effective in the long run.

By understanding the strengths of each technology and aligning them with your business goals, you can make informed decisions that lead to successful outcomes in your 3D prototyping endeavors.

Implementing 3D prototyping in your product development process can significantly enhance your business's efficiency and innovation. According to a report by Statista, 3D printing is expected to grow at a compound annual growth rate (CAGR) of 23.7% from 2021 to 2028, highlighting the increasing adoption of such technologies across various industries. This rapid growth underscores the importance of integrating 3D prototyping techniques early in the product development lifecycle.

To begin, establish a clear workflow by defining the stages of design, development, and testing. Utilize software tools like CAD (Computer-Aided Design) to create precise models and then employ 3D printing to produce physical prototypes. Research from the Wohlers Report points out that 79% of companies utilizing 3D printing found it directly beneficial for speeding up design cycles. By iterating quickly on prototypes, businesses can refine their products based on real-world feedback, ultimately leading to a more successful market launch. Integrating these practices can not only streamline operations but also result in significant cost savings, as reported by Deloitte's analysis showing that businesses can save up to 90% on prototyping costs when leveraging additive manufacturing technologies.

| 3D Prototyping Technique | Description | Benefits | Typical Applications | Recommended Software |

|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | A popular 3D printing technology that adds material layer by layer. | Cost-effective, accessible, and suitable for various materials. | Prototyping, functional testing, and educational models. | TinkerCAD, Ultimaker Cura |

| Stereolithography (SLA) | A process that uses light to cure resin layer by layer. | High precision and smooth finish, ideal for detailed prototypes. | Jewelry making, dental models, and small intricate parts. | Autodesk Fusion 360, Formlabs PreForm |

| Selective Laser Sintering (SLS) | A method that uses laser to sinter powdered material into a solid structure. | Strong and functional parts, suitable for complex geometries. | Functional prototypes and small production runs. | Materialise Magics, Rhino |

| Digital Light Processing (DLP) | Similar to SLA but uses a digital light projector to cure resin. | Fast print time and excellent surface quality. | Art, dental applications, and miniatures. | Chitubox, Elegoo Mercury |

| Multi-Jet Modeling (MJM) | A printer that deposits droplets of material and UV light-cures them. | High resolution and color accuracy, good for visual prototypes. | Architectural models, marketing prototypes, and medical models. | Stratasys, 3D Systems software |

In the evolving landscape of 3D prototyping, businesses face numerous challenges that can impact their success. One primary issue is the range of materials available for different applications, particularly in specialized fields like pharmaceuticals and biomedical devices. The advancements in 3D printing technology now offer solutions for producing complex dosage forms and structures, yet the integration of these innovations remains a hurdle for many companies. Companies must invest in robust testing and validation processes to ensure the reliability and safety of these new forms.

Tip: To address material-related challenges, consider collaborating with research institutions or material suppliers to explore innovative options that suit your specific prototyping needs. Additionally, staying abreast of technological advancements, such as liquid metal 3D printing, can provide new avenues to enhance your prototyping capabilities.

Another significant obstacle is scaling production while maintaining quality. The increasing adoption of large-scale 3D printing equipment has made it feasible to produce at an industrial level, but firms must grapple with operational efficiencies and quality control measures. Embracing automation and data analytics can streamline processes and minimize human error.

Tip: Implementing a feedback loop within your production process can help quickly identify and rectify issues, ensuring that quality is never compromised as you scale. Leveraging AI and IoT technologies can also optimize workflows, enhance monitoring, and facilitate proactive maintenance of 3D printing systems.

In the ever-evolving landscape of modern business, 3D prototyping has emerged as a game-changer, enabling companies to bring their innovative ideas to life with unprecedented speed and precision. Some notable success stories illustrate how enterprises are leveraging these techniques to transform their operations. For instance, a leading apparel company utilized 3D prototyping to drastically reduce the time spent on sample production. By creating lifelike models of garments, they were able to visualize designs quickly and efficiently, allowing for rapid iteration and streamlined decision-making. This newfound agility not only enhanced their product offerings but also drove significant cost savings.

Another fascinating example comes from the automotive industry, where a major manufacturer adopted 3D printing technologies to prototype parts for new vehicle models. This approach allowed them to test performance in real-world conditions before large-scale production, cutting back on both time and resources. The manufacturer reported not only improved efficiency in their design process but also a notable increase in collaboration among teams, showcasing how 3D prototyping can foster innovation within a company. These real-world applications underscore the vast potential of 3D prototyping techniques, proving that with the right tools, businesses can achieve remarkable transformations and stay ahead in a competitive market.

This chart illustrates the impact of various 3D prototyping techniques on business success. The data represents the percentage increase in product development speed and cost efficiency across different techniques used by businesses in the past year.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |