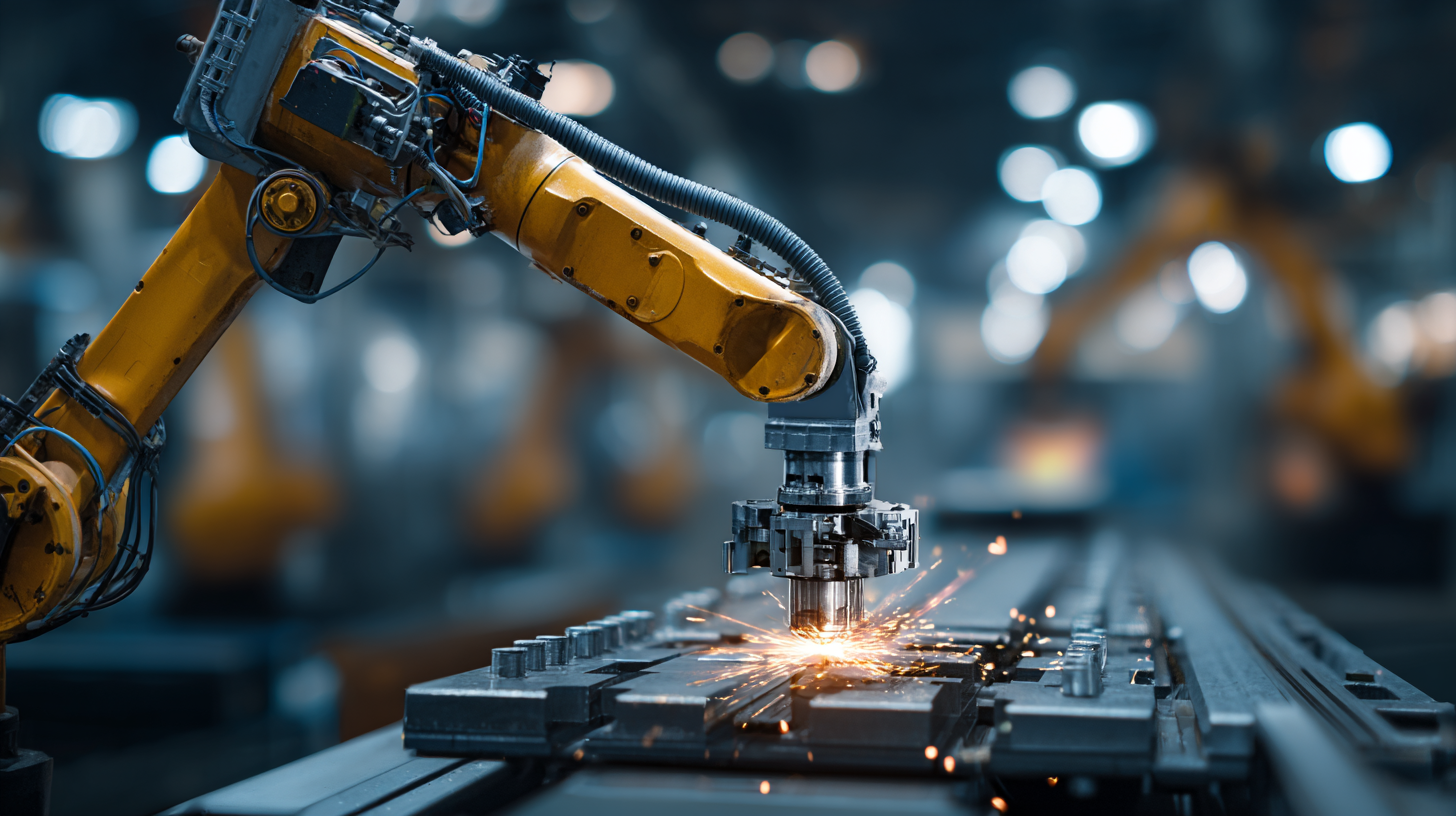

In today's fast-paced manufacturing landscape, rapid metal prototyping has emerged as a pivotal solution for companies seeking to innovate and streamline their production processes. This advanced technology allows manufacturers to quickly create metal prototypes, significantly reducing the time from concept to market. As industries strive for increased efficiency and reduced costs, understanding the importance of rapid metal prototyping becomes crucial.

By leveraging this method, businesses can enhance product design, facilitate faster testing and iterations, and ultimately improve overall quality. This blog will delve into the core benefits of rapid metal prototyping, offering tips and insights into how embracing this approach can transform modern manufacturing practices and drive competitive advantage.

Rapid metal prototyping has emerged as a pivotal process in modern manufacturing, significantly accelerating product development cycles. According to a survey conducted by the American Society for Mechanical Engineers (ASME), companies utilizing rapid prototyping techniques saw a 30% reduction in product development time. This expedited process allows for quick iterations in designs, enabling engineers to conduct tests and make modifications promptly, which is crucial in today’s highly competitive market where speed to market can define industry leaders.

To maximize the benefits of rapid metal prototyping, consider the following tips: First, prioritize choosing the right materials for your prototypes, as this will affect their performance and durability during testing. Second, engage in multidisciplinary collaboration early in the design phase. Cross-functional teams can provide diverse perspectives, ensuring that the end product aligns with both engineering specifications and market needs. Lastly, invest in advanced technologies such as metal 3D printing and CNC machining, which can improve precision and reduce waste, contributing to overall cost-efficiency in product development.

By integrating rapid metal prototyping into the manufacturing process, companies not only enhance their innovation capabilities but also significantly decrease time and costs associated with traditional methods. Industries from automotive to aerospace are embracing this evolution, recognizing its long-term advantages in maintaining competitiveness.

Rapid prototyping has revolutionized modern manufacturing by offering significant cost savings and time efficiency. One of the primary advantages of rapid metal prototyping lies in its ability to produce components quickly, allowing manufacturers to bring their products to market much faster than traditional methods. This expedited process reduces the lead time dramatically, enabling companies to test and refine their designs swiftly. As a result, manufacturers can adapt to market changes or customer feedback without incurring substantial costs.

Moreover, the cost savings associated with rapid prototyping are substantial. Traditional prototyping methods often involve lengthy setup times and expensive tooling. In contrast, rapid prototyping employs advanced techniques such as 3D printing or CNC machining, which minimizes material waste and labor costs. By utilizing these technologies, manufacturers can produce high-quality prototypes at a fraction of the cost, ultimately enhancing their return on investment. This is particularly beneficial for small to medium-sized enterprises looking to innovate without the burden of high overhead expenses.

| Benefit | Description | Estimated Savings (%) | Time Reduction (Weeks) |

|---|---|---|---|

| Cost Efficiency | Reduced material waste and lower overhead costs through efficient production methods. | 20-30% | 2-3 Weeks |

| Fast Turnaround | Accelerated design and production cycles allowing quicker market entry. | 15-25% | 3-4 Weeks |

| Design Flexibility | Ability to tweak designs easily based on testing and customer feedback. | Variable | 1-2 Weeks |

| Risk Mitigation | Identifying potential production issues early through prototype testing. | 10-15% | 2 Weeks |

| Enhanced Collaboration | Improved communication among stakeholders facilitated by physical prototypes. | Variable | 1 Week |

Rapid metal prototyping is revolutionizing various industries by providing a strategic advantage in product development. According to a report by Wohlers Associates, the additive manufacturing market, which includes rapid prototyping technology, is projected to reach $35.6 billion by 2024. This growth reflects the expanding recognition of rapid prototyping's ability to expedite the design process and reduce time-to-market.

Industries such as aerospace, automotive, and medical are at the forefront of leveraging rapid metal prototyping. For instance, aerospace companies are utilizing this technology to create lightweight component designs that enhance fuel efficiency. A study from the National Center for Advanced Technologies suggests that aerospace manufacturers can save up to 60% in costs and reduce lead times by 67% when implementing rapid prototyping methods. Similarly, the automotive sector is adopting rapid prototyping to streamline the testing of parts, accelerating the development cycle and allowing for more innovative designs. This adaptability not only fosters competitive advantage but also drives overall industry advancement.

Rapid metal prototyping has emerged as a game-changing process in modern manufacturing, significantly differing from traditional methods. Traditional prototyping techniques often involve lengthy lead times, considerable material waste, and a less flexible design iteration process. In contrast, rapid metal prototyping leverages advanced additive manufacturing (AM) technologies, allowing for the production of complex geometries with greater precision and reduced costs. According to recent studies, AM can improve production efficiency in the aerospace and automotive industries, providing cost-effective and environmentally friendly solutions that meet the evolving demands for sustainability.

The comparative advantages of rapid metal prototyping are underscored by a systematic review showcasing that frameworks fabricated by CAD/CAM and rapid prototyping techniques exhibited superior fit accuracy compared to conventional methods. This finding underscores the efficacy of rapid prototyping in maintaining high standards of quality, while also facilitating more efficient workflows. Moreover, the integration of multi-material additive manufacturing has garnered substantial attention, enabling the creation of components with enhanced functionality and reduced weight, which is particularly beneficial in industries focused on innovation and sustainability. As these technologies continue to develop, they promise to redefine manufacturing paradigms and enhance product development avenues.

In recent years, metal prototyping has undergone significant transformations driven by technological advancements. The rise of additive manufacturing techniques, such as metal 3D printing, has revolutionized the prototyping landscape. This innovation not only enhances the precision and complexity of designs but also drastically reduces lead times. As manufacturers embrace these new technologies, we are witnessing a shift towards more customized and lightweight solutions that cater to the increasing demands of various industries, including aerospace, automotive, and medical sectors.

Looking ahead, the market for metal prototyping is projected to experience robust growth. Emerging trends such as hybrid manufacturing—integrating traditional methods with modern additive techniques—are set to redefine production paradigms. Additionally, sustainability is becoming a pivotal focus; practices aimed at minimizing waste and improving energy efficiency during the prototyping process are gaining traction. Companies that adapt to these innovative trends and align their strategies accordingly will be well-positioned to thrive in a competitive market where speed and quality are paramount.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |