In today's fast-paced market, the need for quick and efficient product development has never been more critical. As businesses strive to keep up with consumer demands and technological advancements, rapid tooling emerges as a pivotal strategy to enhance the development process. By leveraging rapid tooling techniques, organizations can streamline prototyping, reduce lead times, and achieve higher levels of design flexibility. This approach not only accelerates the time from concept to market but also fosters innovation by allowing for iterative testing and refinement of designs.

Implementing rapid tooling involves utilizing advanced manufacturing methods, such as 3D printing and injection molding, to create prototypes and production tools at an unprecedented speed. These techniques enable teams to produce high-quality parts quickly and affordably, which is essential in a competitive landscape where speed to market often determines success. This introduction to rapid tooling underscores its significance in modern product development, setting the stage for a detailed exploration of best practices, methodologies, and case studies that showcase its transformative impact in various industries.

Ultimately, adopting rapid tooling can catalyze a shift in how products are designed and developed, making it an indispensable component of an agile manufacturing environment. By embracing this approach, companies position themselves to respond swiftly to changing market conditions and customer preferences, ensuring they remain at the forefront of innovation and efficiency.

Rapid tooling refers to the accelerated process of creating molds and tools necessary for manufacturing products, significantly shortening the traditional development cycle. In product development, this approach plays a crucial role by enabling quicker prototype iterations and facilitating immediate feedback from both designers and users. By utilizing advanced technologies, such as additive manufacturing and CNC machining, rapid tooling allows teams to bring their concepts to life faster than conventional methods, thus enhancing innovation and responsiveness to market demands.

The importance of rapid tooling in product development cannot be overstated. It fosters collaboration among cross-functional teams by providing tangible prototypes that can be tested and refined in real time. This iterative process not only identifies design flaws early on but also helps align stakeholder expectations. Moreover, the reduction in lead time significantly impacts cost management, allowing businesses to allocate resources more efficiently and improve overall profitability. In an increasingly competitive landscape, the ability to develop and launch products rapidly can be a key differentiator for companies seeking to meet evolving consumer needs.

| Dimension | Description | Importance in Product Development |

|---|---|---|

| Lead Time | The duration from concept to prototype. | Shortening lead time accelerates market entry. |

| Cost Efficiency | Reduction in production costs through advanced tooling. | Lower costs enable pricing flexibility and competitiveness. |

| Flexibility | Ability to quickly adapt designs based on feedback. | Enhanced responsiveness to market demands. |

| Quality Assurance | Ensuring high fidelity prototypes for testing. | Improved product reliability and customer satisfaction. |

| Collaboration | Facilitates teamwork between designers and engineers. | Strengthens innovation through diverse input. |

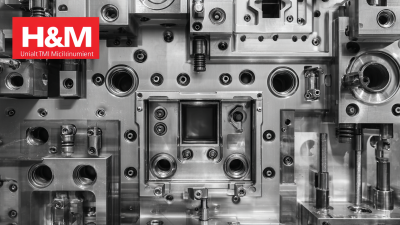

Rapid tooling has emerged as a vital component in accelerating product development across various industries. The implementation of this approach involves utilizing advanced manufacturing techniques and materials to create prototypes and tooling rapidly, streamlining the entire development process. Key methods include additive manufacturing, which allows for the quick fabrication of molds and tooling components, and CNC machining, which offers precision and speed in producing parts. These techniques empower businesses to reduce the lead time significantly while maintaining high-quality standards.

In sectors such as automotive, aerospace, and consumer goods, rapid tooling methods enable teams to iterate designs more effectively. For instance, incorporating 3D printing technology can produce complex geometries that traditional manufacturing methods may struggle to achieve. Additionally, digital simulation tools play a crucial role in validating designs before physical production, reducing wastage and enhancing efficiency. By fostering collaboration between design and manufacturing teams, organizations can ensure that rapid tooling becomes an integral part of their product development strategy, ultimately leading to quicker market readiness and increased competitiveness.

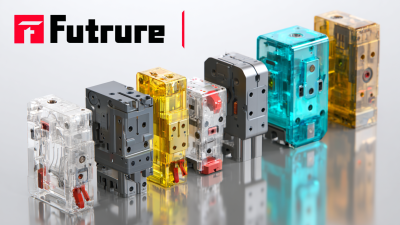

When implementing rapid tooling for faster product development, one of the most critical aspects is the evaluation of materials and technologies. The choice of material can significantly influence not only the speed of the tooling process but also the quality and functionality of the final product. Materials like thermoplastics, metals, and composites each present unique advantages and limitations. For instance, while thermoplastics may allow for quicker production times, metals might offer superior strength and durability. Understanding the specific requirements of the end product will guide the material selection, ensuring that it meets performance standards without sacrificing time efficiency.

In addition to materials, the technologies employed in rapid tooling play a vital role in the development cycle. Techniques such as 3D printing, CNC machining, and injection molding each have their strengths that can be leveraged depending on the project's needs. 3D printing, for example, offers flexibility in design and the ability to create complex geometries rapidly, making it a favored option for prototyping. Meanwhile, traditional methods like CNC machining provide precision and material choice that may be essential for production-quality components. Evaluating these technologies in conjunction with materials will help in crafting a comprehensive strategy that maximizes productivity while ensuring that the end product aligns with market demands.

Effectively managing rapid tooling projects and schedules is crucial for accelerating product development. One best practice is to establish clear communication channels among all team members from the outset. Regular updates and check-ins can help ensure everyone is aligned on goals, timelines, and potential challenges. Utilizing project management tools can streamline this process, enabling teams to track progress in real-time, assign responsibilities, and make adjustments as necessary. This proactive approach minimizes delays and keeps projects on schedule, fostering a collaborative environment.

Another important strategy is to prioritize tasks based on their impact on project deadlines. By identifying critical paths and bottlenecks early on, teams can allocate resources more effectively to areas that require immediate attention. Incorporating agile methodologies allows for flexibility in scheduling, encouraging iterative progress and rapid feedback loops. Additionally, investing in training for team members on the latest tooling technologies can enhance their efficiency, ensuring that the project remains on track while also harnessing innovative solutions for product development.

The impact of rapid tooling on product development cycles can be significant, resulting in reduced time-to-market and enhanced operational efficiency. According to a report by AMFG, companies utilizing rapid tooling can see their product development timelines shortened by as much as 50%. This acceleration is primarily due to the ability to create prototypes and molds in a fraction of the time compared to traditional methods, allowing for iterative testing and quick modifications based on feedback. Furthermore, the reliance on additive manufacturing techniques can lead to substantial cost savings by minimizing material waste and reducing setup times.

Tips: To maximize the benefits of rapid tooling, companies should implement a clear strategy that prioritizes collaboration between design and engineering teams. By facilitating open communication, teams can ensure that design specifications can be efficiently translated into workable prototypes. Additionally, investing in training for employees on the latest rapid tooling technologies can enhance their skill sets and promote innovative approaches to product development.

The shift towards rapid tooling is also backed by a study from Deloitte, which indicates that 70% of manufacturers are exploring or implementing rapid tooling solutions. This growing trend highlights the necessity for companies to assess their current processes critically and consider integrating rapid tooling into their workflows. By adopting these methodologies, businesses can remain competitive in the ever-evolving market landscape and respond promptly to consumer demands.

This chart illustrates the correlation between the implementation of rapid tooling and the reduction in product development cycle time across various industries. As the rapid tooling methodologies advance, a significant decrease in the development time can be observed.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |