Rapid sheet metal fabrication has emerged as a transformative force in modern manufacturing, significantly enhancing efficiency and responsiveness in production processes. As industries increasingly demand shorter lead times and greater customization, the rapid turnaround capabilities of sheet metal fabrication are proving crucial. According to a recent report by Allied Market Research, the global sheet metal fabrication market is projected to reach $24.6 billion by 2027, driven by advancements in technology and the growing emphasis on streamlined production workflows. Furthermore, a study by the Fabricators & Manufacturers Association reports that manufacturers employing rapid sheet metal fabrication techniques have experienced productivity improvements of up to 30%. This highlights how integrating such innovative approaches not only meets market demands but also drives competitive advantage, making rapid sheet metal fabrication an essential component of modern manufacturing strategies.

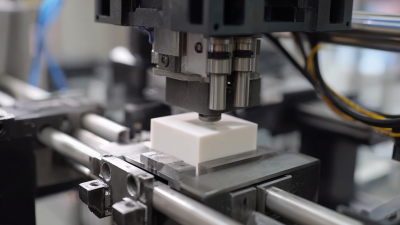

Rapid sheet metal fabrication is revolutionizing the manufacturing landscape by significantly reducing lead times, a critical factor for many industries. According to a 2022 report from the Fabricators & Manufacturers Association, companies utilizing rapid prototyping techniques in sheet metal fabrication have seen lead times reduced by an impressive 50-70%. This efficiency is largely attributed to advanced technologies such as laser cutting and CNC machining, which streamline production processes and minimize the need for extensive tooling.

Moreover, rapid sheet metal fabrication not only accelerates production but also enhances flexibility in design changes. The ability to quickly iterate designs means manufacturers can respond to market demands and customer feedback without the traditional delays. A 2023 study conducted by the Manufacturing Institute highlights that firms that embrace rapid fabrication often report a 30% increase in project turnover, enabling them to take on more projects within the same timeframe. This adaptability is crucial in today’s fast-paced market, where time-to-market can be a decisive factor for business competitiveness.

Rapid sheet metal fabrication has emerged as a game changer in the manufacturing sector, significantly lowering production costs while enhancing efficiency. Traditional manufacturing methods often involve prolonged lead times and higher labor expenses, which can inflate the overall costs of production. In contrast, rapid sheet metal fabrication utilizes advanced technology and automated processes to streamline production, enabling manufacturers to produce parts in a fraction of the time. This efficiency not only reduces labor costs but also minimizes material waste, further cutting down expenses.

Rapid sheet metal fabrication has emerged as a game changer in the manufacturing sector, significantly lowering production costs while enhancing efficiency. Traditional manufacturing methods often involve prolonged lead times and higher labor expenses, which can inflate the overall costs of production. In contrast, rapid sheet metal fabrication utilizes advanced technology and automated processes to streamline production, enabling manufacturers to produce parts in a fraction of the time. This efficiency not only reduces labor costs but also minimizes material waste, further cutting down expenses.

Tips: When considering rapid sheet metal fabrication, be sure to evaluate your design for manufacturability. Simplifying designs can result in less material usage and lower costs. Additionally, opt for a manufacturer that offers integrated services, including design, prototyping, and finishing, to further streamline the process and reduce ordering fragmentation.

The cost benefits extend beyond just initial production expenses. Rapid sheet metal fabrication allows for quicker time-to-market, which can enhance competitive advantage and potentially lead to increased sales. Moreover, the flexibility of rapid fabrication techniques enables the quick adaptation of designs based on market demands, allowing businesses to pivot and innovate without incurring significant retooling costs.

In the modern landscape of manufacturing, rapid sheet metal fabrication has become pivotal in enhancing product precision. According to a report by SME (Society of Manufacturing Engineers), advanced fabrication technologies can reduce the production time by up to 50%, while simultaneously increasing dimensional accuracy to as low as ±0.5 mm. This significant improvement in quality control enables manufacturers to meet stringent specifications and tight tolerances, ensuring higher product performance and reliability.

Furthermore, leveraging smart technologies such as laser cutting and robotic welding has proven to be transformative. A recent study by McKinsey & Company indicates that companies implementing these advanced methodologies experience an increase in overall productivity by approximately 20-30%. This shift not only enhances efficiency but also allows for more intricate designs that were previously not achievable through traditional methods. The combination of rapid fabrication techniques and sophisticated quality control processes not only streamlines workflows but also positions manufacturers to respond swiftly to market demands while maintaining exceptional product standards.

Rapid sheet metal fabrication plays a pivotal role in enhancing modern manufacturing efficiency while simultaneously promoting sustainability. By utilizing advanced technologies like CNC machining and laser cutting, manufacturers can produce high-precision parts with significantly reduced lead times. This efficiency not only accelerates production but also contributes to lower energy consumption and decreased material waste, aligning closely with eco-friendly practices.

Rapid sheet metal fabrication plays a pivotal role in enhancing modern manufacturing efficiency while simultaneously promoting sustainability. By utilizing advanced technologies like CNC machining and laser cutting, manufacturers can produce high-precision parts with significantly reduced lead times. This efficiency not only accelerates production but also contributes to lower energy consumption and decreased material waste, aligning closely with eco-friendly practices.

The surge in precision manufacturing techniques enables companies to optimize their resource utilization. Traditional methods often resulted in excess scrap metal and inefficient processes; however, rapid fabrication minimizes this waste by allowing for more precise cuts and designs. Additionally, many manufacturers are adopting recyclable materials and sustainable practices in their operations, ensuring that their production processes contribute positively to the environment. This commitment to sustainability not only enhances a company's brand reputation but also adheres to the growing market demand for eco-conscious products, making rapid sheet metal fabrication a win-win for both efficiency and environmental responsibility.

Rapid sheet metal fabrication is transforming the landscape of modern manufacturing, enabling companies to enhance efficiency and reduce lead times significantly. Case studies across various industries illustrate the successful implementation of this technology, showcasing its ability to streamline production processes. For instance, manufacturers leveraging rapid sheet metal techniques have reported faster turnaround times for prototypes, allowing them to quickly iterate designs based on market feedback. This agility facilitates a more responsive approach to production, addressing customer needs more effectively.

A notable example of rapid sheet metal fabrication's impact can be seen in organizations that have embraced digital transformation strategies. Recently, a leading company in the industry received multiple national honors for its innovative use of industrial internet platforms and smart manufacturing techniques. This recognition highlights how integrating advanced fabrication methods can lead to not just operational improvements, but also to accolades that validate a company's commitment to modernization and efficiency. As more businesses adopt such practices, the overall landscape of manufacturing is set to evolve, encouraging a shift towards more intelligent and adaptable production environments.

| Application Area | Efficiency Improvement (%) | Lead Time Reduction (days) | Material Waste Reduction (%) | Cost Savings (%) |

|---|---|---|---|---|

| Aerospace Components | 30 | 5 | 20 | 15 |

| Automotive Parts | 25 | 4 | 18 | 10 |

| Consumer Electronics | 35 | 3 | 22 | 20 |

| Industrial Equipment | 20 | 6 | 15 | 12 |

| Medical Devices | 28 | 5 | 19 | 18 |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |