The quick turn injection molding market is poised for significant growth, with a projected increase in demand driven by the need for faster production cycles and high-quality components across various industries. According to a recent report by MarketsandMarkets, the global quick turn injection molding market is expected to reach USD 8.9 billion by 2025, reflecting a CAGR of 7.5% from 2020. As companies strive to innovate and reduce time-to-market for their products, identifying reliable suppliers for quick turn injection molding becomes critical. In this competitive landscape, manufacturers must not only focus on the quality and efficiency of the injection molding process but also seek suppliers who can offer advanced technologies and flexibility in production. This blog will explore the essential criteria for evaluating potential suppliers and provide insights into how to effectively navigate the market to find the best partners for your quick turn injection molding needs.

The quick turn injection molding market is poised for significant growth, with a projected increase in demand driven by the need for faster production cycles and high-quality components across various industries. According to a recent report by MarketsandMarkets, the global quick turn injection molding market is expected to reach USD 8.9 billion by 2025, reflecting a CAGR of 7.5% from 2020. As companies strive to innovate and reduce time-to-market for their products, identifying reliable suppliers for quick turn injection molding becomes critical. In this competitive landscape, manufacturers must not only focus on the quality and efficiency of the injection molding process but also seek suppliers who can offer advanced technologies and flexibility in production. This blog will explore the essential criteria for evaluating potential suppliers and provide insights into how to effectively navigate the market to find the best partners for your quick turn injection molding needs.

As we look towards 2025, the quick turn injection molding market is poised for significant transformation, driven by rapid technological innovations. One of the most notable trends is the integration of advanced materials, such as bio-based plastics and composites. These materials not only enhance product performance but also contribute to more sustainable manufacturing practices. This shift toward eco-friendly options will likely reshape consumer expectations and influence market demand, pushing manufacturers to innovate continually.

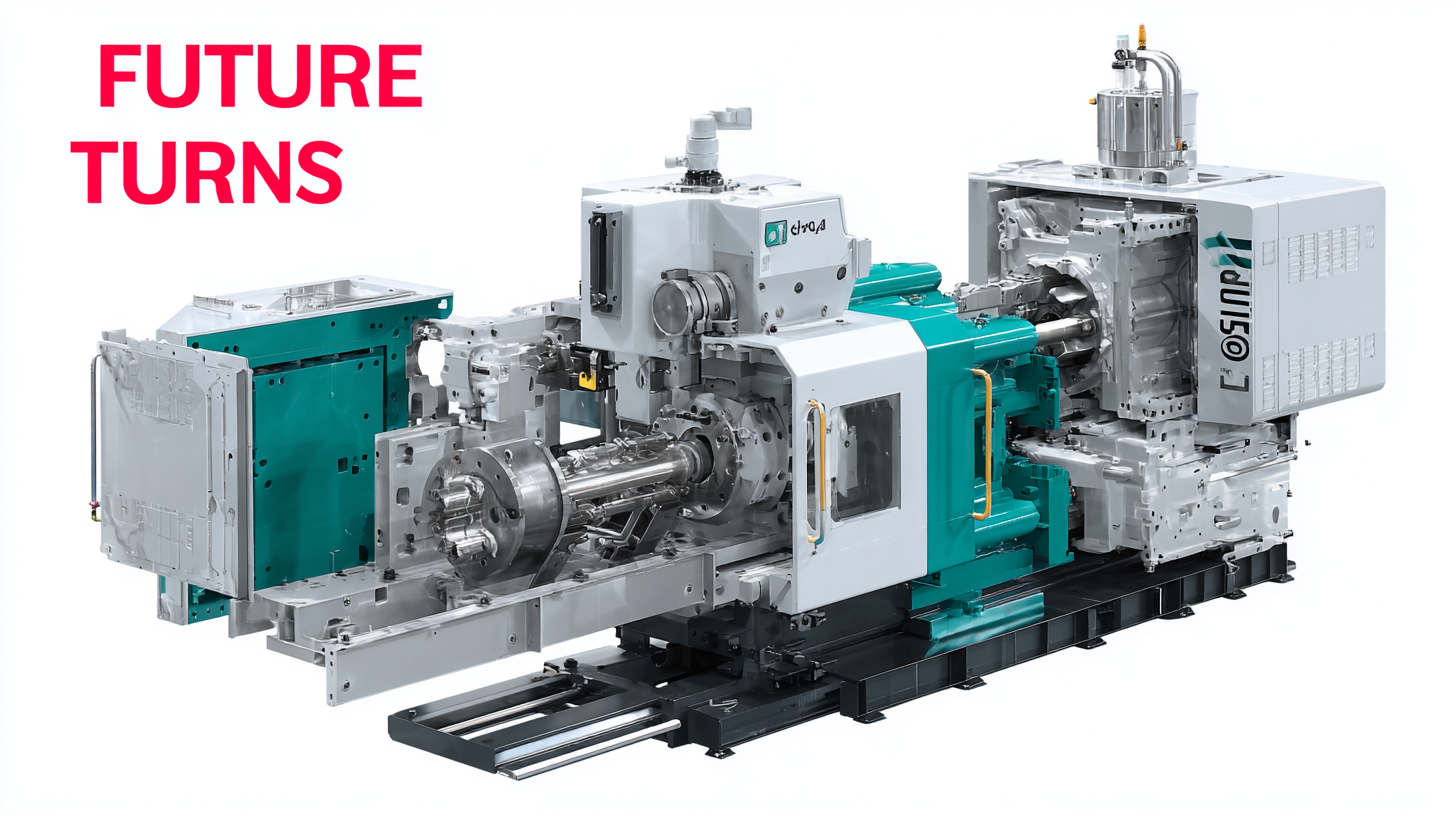

Moreover, automation and AI technologies are set to revolutionize the operational capabilities of quick turn injection molding processes. Smart factories utilizing data analytics and machine learning will enable real-time monitoring and predictive maintenance, thereby reducing downtime and increasing efficiency. The use of robotics in production lines will also streamline operations, ensuring faster turnaround times and higher precision in molding complex designs. By 2025, we can expect these advancements to not only enhance the speed of production but also to elevate the quality and customization options available in the market.

The adoption of advanced quick turn injection molding techniques is rapidly transforming the manufacturing landscape, offering significant advantages for companies aiming to enhance efficiency and production quality. According to a recent market analysis by Mordor Intelligence, the global quick turn injection molding market is projected to reach USD 12 billion by 2025, growing at a CAGR of 8.4%. This growth is largely driven by industries such as automotive, consumer goods, and medical devices, which require rapid prototyping and high precision.

One of the key benefits of these advanced techniques is the reduction in lead times. By leveraging state-of-the-art technologies, manufacturers can significantly shorten the time from design to production, allowing for rapid iteration and quicker responses to market demands. It is estimated that companies utilizing quick turn injection molding can shorten their product development cycles by up to 30%, a crucial factor in today’s fast-paced marketplace.

Tip: To maximize the effectiveness of quick turn injection molding, companies should invest in training their teams on the latest technologies and software that streamline the design and production processes.

Additionally, incorporating automation in injection molding processes not only enhances precision but also reduces labor costs. A report from Grand View Research indicates that automating the injection molding process can lead to savings of around 20% in production costs, emphasizing its importance for manufacturers seeking to remain competitive.

Tip: Regularly assess and update your equipment to integrate automated solutions that can align with your production goals and capacity.

The Quick Turn Injection Molding market is poised for substantial growth by 2025, reflecting a trend towards faster production cycles and the increasing demand for customized manufacturing solutions. According to recent market analyses, the global plastic injection molding market is projected to reach USD 13.19 billion by 2025, with a compound annual growth rate (CAGR) of 4.12% extending to 2033. This growth is driven by the rising adoption of quick turn services, which cater to the need for rapid prototyping and short-production runs, crucial for industries such as automotive and consumer electronics.

Additionally, the automotive mold market is expected to experience a remarkable surge, with its size projected to increase from USD 48.13 billion in 2025 to USD 82.35 billion by 2034. This expansion underscores the essential role of quick turn injection molding in supporting the automotive sector's demand for lightweight, high-performance components that meet stringent performance and safety standards. With specialized tools and materials like thermoplastic polyurethane, manufacturers are increasingly able to deliver innovative solutions that meet fast-paced market requirements while ensuring quality and efficiency in production.

The quick turn injection molding market is witnessing a significant shift towards sustainability, driven by an increasing demand for eco-friendly materials. As industries evolve, the use of bio-polypropylene is gaining traction, projected to reach USD 1,160.28 million by 2029. This material, derived from renewable resources, not only reduces dependence on fossil fuels but also offers comparable performance to traditional plastics. Companies are increasingly leveraging such materials to meet consumer preferences for sustainable products, ultimately reshaping the manufacturing landscape.

Moreover, the integration of digitalization and Industry 4.0 is revolutionizing manufacturing processes, allowing for enhanced efficiency and sustainability. Automated systems and data analytics are optimizing resource use, reducing waste, and improving overall production timelines. As manufacturers adopt these technologies along with eco-friendly materials, they position themselves to meet both market demands and environmental goals, creating a synergy that will define the future of quick turn injection molding and beyond.

| Year | Market Size (Million USD) | Eco-Friendly Material Adoption (%) | Sustainability Initiatives (%) | Technological Advancements (%) |

|---|---|---|---|---|

| 2023 | 1200 | 25 | 15 | 10 |

| 2024 | 1350 | 30 | 20 | 15 |

| 2025 | 1500 | 40 | 25 | 20 |

The quick turn injection molding market is undergoing a transformative evolution driven by the integration of automation and artificial intelligence (AI). By 2025, these technologies are expected to redefine operational efficiency, significantly shortening production cycles while maintaining quality. Automation enhances the speed of the molding process, allowing for rapid setup changes and minimizing human error. This shift enables manufacturers to respond to market demands swiftly, producing customized parts at a lower cost and within shorter timeframes.

AI plays a crucial role in optimizing the injection molding process. Machine learning algorithms analyze vast amounts of data to predict equipment maintenance needs, reducing downtime and enhancing the overall production timeline. Additionally, AI-powered design tools can efficiently simulate various molding scenarios, leading to innovative solutions that cater to customers' specific requirements. Together, automation and AI not only streamline operations but also empower companies to achieve greater precision, thus paving the way for the future of quick turn injection molding. As these trends unfold, businesses that embrace these technologies will likely gain a competitive edge in the ever-evolving marketplace.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |