As we move towards 2025, the landscape of 3D prototyping is poised for transformative change, driven by advancements in digital technologies and a growing demand from global buyers. According to a recent report by MarketsandMarkets, the 3D printing market is expected to reach $34.8 billion by 2024, with a substantial portion of this growth attributed to enhanced prototyping techniques and materials. This evolution is redefining not only how products are designed but also how they are manufactured and brought to market, emphasizing the integration of digital solutions like artificial intelligence and machine learning.

As businesses seek to innovate faster and reduce time-to-market, understanding future trends in 3D prototyping will be critical for global buyers aiming to stay competitive in an increasingly fast-paced economic environment.

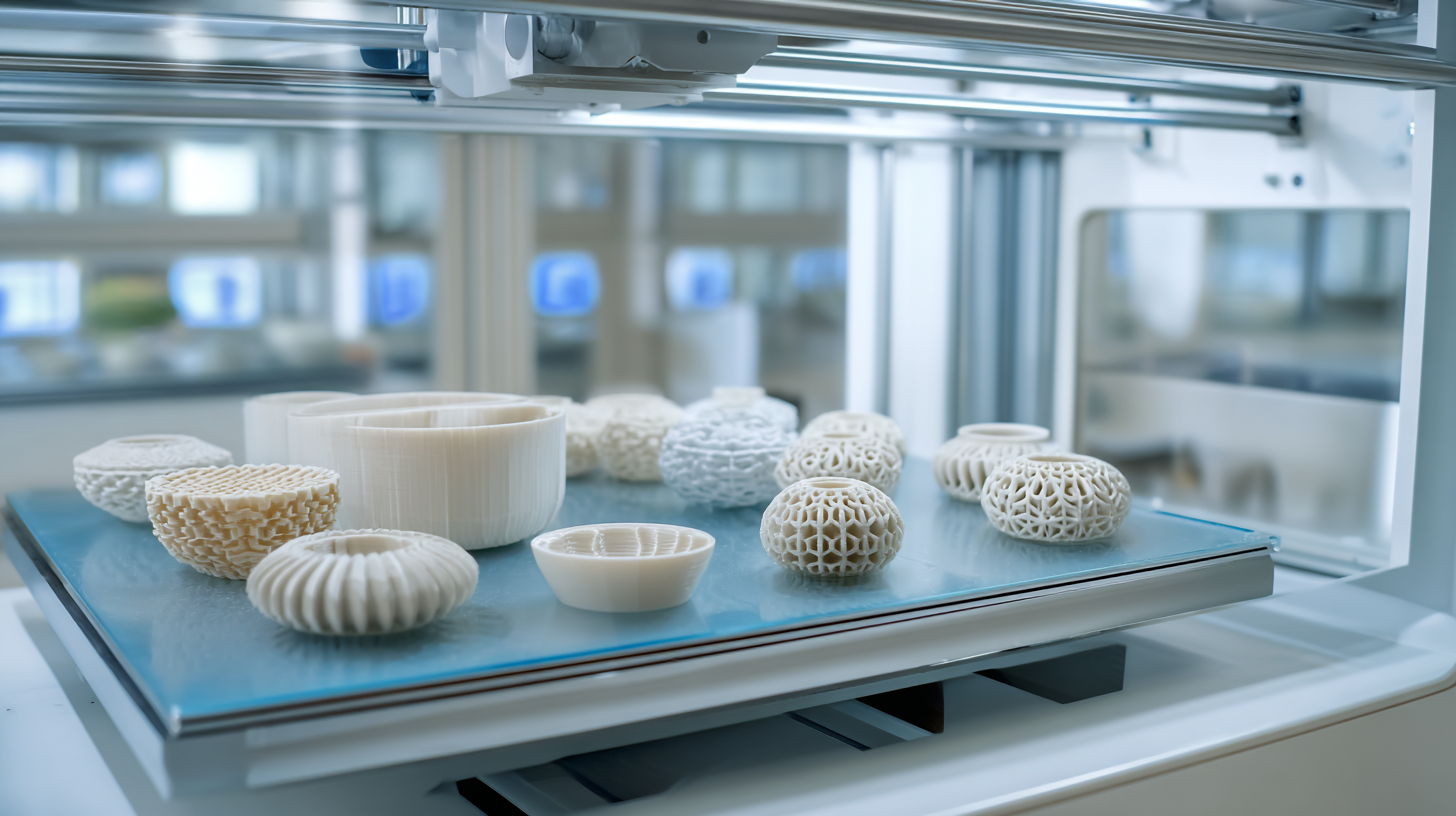

The evolution of 3D prototyping technologies is set to transform the landscape of product development by 2025. With the global 3D printing market projected to reach $34.8 billion by 2024, the integration of advanced techniques such as generative design and artificial intelligence is becoming increasingly pivotal. As businesses strive for more efficient production methods, innovations in materials and processes will enable companies to not only reduce costs but also enhance customization capabilities, fostering a rapid response to market demands. Reports indicate that approximately 60% of manufacturing firms are already utilizing some form of 3D printing technology, underscoring its growing prominence in the industry.

**Tip:** To stay ahead in this competitive market, businesses should invest in training their workforce on the latest 3D printing technologies and materials. This proactive approach will not only improve efficiency but also spark creativity and innovation within the organization.

As 3D prototyping continues to evolve, sustainability will also play a critical role. The rise of biodegradable and recyclable materials is reshaping the way products are conceived and produced. According to research, nearly 80% of consumers are willing to pay more for sustainable products, highlighting the market's shift towards environmentally friendly practices. Companies that embrace this trend by adopting sustainable prototyping techniques will not only satisfy consumer demands but also differentiate themselves in a crowded marketplace.

**Tip:** Consider partnering with suppliers who prioritize sustainable practices. This collaboration can enhance brand reputation and appeal to the growing segment of environmentally-conscious consumers.

The landscape of 3D prototyping is poised for significant transformation by 2025, driven by key industry standards that are fostering innovation across various sectors. According to a report by Wohlers Associates, the global 3D printing market is projected to reach $35.6 billion by 2024, reflecting the increasing adoption of additive manufacturing technologies. With these advancements, standards such as ASTM and ISO are becoming crucial as they define quality benchmarks and streamline processes, ensuring interoperability and reliability across different systems.

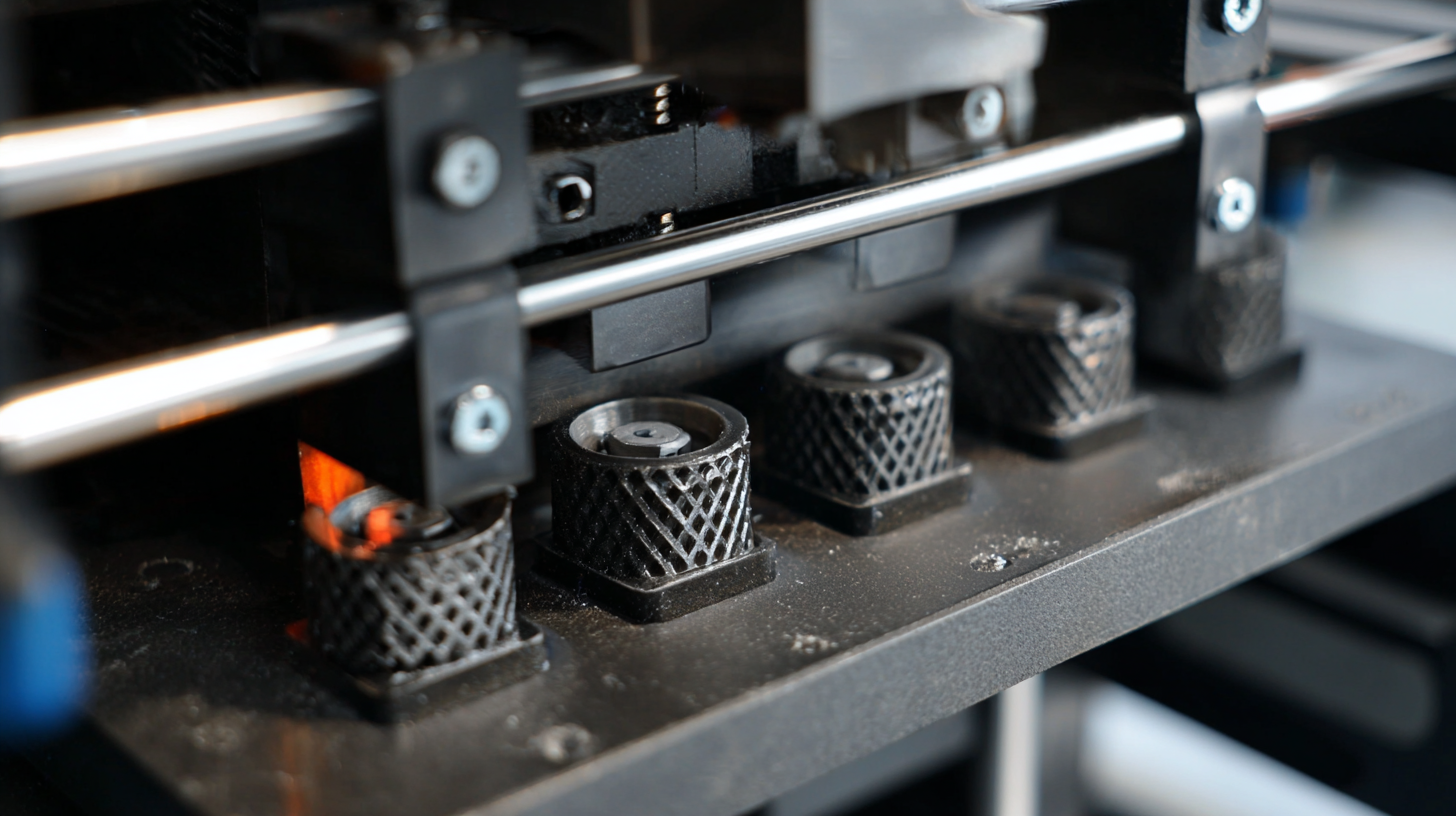

Moreover, the rise of Industry 4.0 and the Internet of Things (IoT) is compelling the 3D prototyping industry to embrace smart manufacturing principles. A market report from MarketsandMarkets predicts that the smart manufacturing sector, closely tied to 3D prototyping, will grow from $214 billion in 2019 to $384 billion by 2025. This emphasizes the need for robust standards that not only enhance design flexibility but also improve sustainability measures. As companies strive to reduce waste and optimize resources in their prototyping processes, adherence to these standards will be key to fostering innovations that are both efficient and environmentally friendly.

As we approach 2025, sustainability is becoming a pivotal component in the realm of 3D prototyping, especially for global buyers. Innovations in sustainable materials are shaping how industries approach design and production. From biocomposites to recycled plastics, the incorporation of eco-friendly materials not only addresses environmental concerns but also enhances the performance of prototypes. These advancements in material technology offer exciting possibilities for brands looking to reduce their carbon footprint while maintaining high quality and functionality in their products.

Moreover, the integration of AI-driven design tools has revolutionized the prototyping process, enabling fashion and industrial designers to predict market trends and customize products more efficiently. The speed of 3D printing allows for rapid prototyping cycles, which is critical for companies seeking to innovate quickly. In addition to sustainability, the 3D printing materials market is projected to grow significantly, with an increasing emphasis on transitioning to greener alternatives.

This shift is not only beneficial for the planet but also appeals to conscious consumers who prioritize sustainable practices in their purchasing decisions. As global buyers navigate these trends, the collaboration between technological advancements and sustainable practices will define the future landscape of 3D prototyping.

The incorporation of artificial intelligence (AI) and automation in 3D prototyping is poised to redefine the manufacturing landscape by 2025. AI is not only increasing efficiency but also transforming the design process, allowing businesses to prototype products more rapidly and effectively. According to recent industry reports, companies that implement AI in their prototyping stages can see design lead times reduced by up to 30%. This acceleration enables global buyers to adapt to market demands swiftly while harnessing innovative designs.

In the process of AI-enabled prototyping, automation tools allow designers to focus on creativity rather than being bogged down by repetitive tasks. For instance, AI algorithms can analyze previous designs and consumer feedback to generate new concepts, thus enhancing the overall user experience. Tips for leveraging AI in your prototyping process include regularly updating your design software to include the latest AI tools and fostering a culture that embraces technological advancements within your team.

Furthermore, as industries increasingly adopt AI in their workflows, it's essential to remain agile. A recent study indicated that teams utilizing AI-driven platforms have seen a 40% increase in productivity levels, which fundamentally shifts the competitive landscape. By integrating AI into prototyping, businesses not only improve their efficiency but also open new avenues for innovation and creativity in product design.

In 2025, the landscape of 3D prototyping is set to be dramatically transformed by emerging materials and innovative techniques. According to a report from the Wohlers Associates, the global 3D printing industry is projected to reach $35.6 billion by 2024, marking a significant shift towards more advanced applications and materials. Key among these emerging materials are bio-based plastics and advanced composites, which offer both sustainability and improved performance. With a growing demand for environmentally friendly solutions, many companies are pivoting to materials like PLA and rPLA, showcasing a notable reduction in carbon footprint while maintaining high structural integrity.

In addition to materials, breakthroughs in printing technologies will further shape the industry. Techniques such as multi-material 3D printing and digital light processing (DLP) are gaining traction, enabling the production of complex geometries with unmatched precision. Research indicates that DLP is expected to grow at a compound annual growth rate (CAGR) of over 29% from 2021 to 2028. This advancement not only enhances the versatility of prototyping but also reduces lead times, allowing businesses to accelerate product development cycles. As these trends gain momentum, global buyers will need to adapt quickly to leverage the full potential of modern 3D prototyping techniques.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |