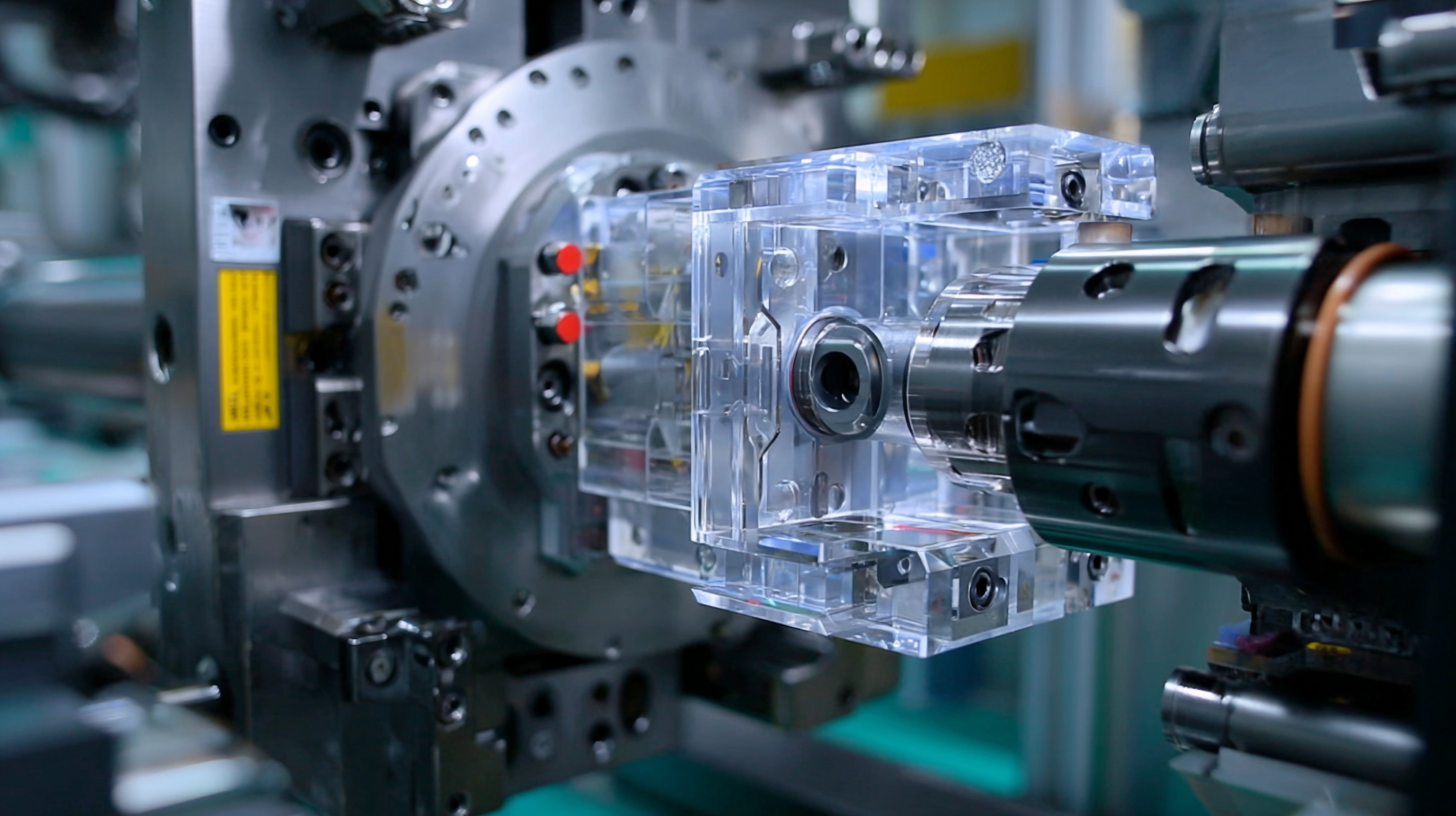

The landscape of manufacturing is evolving at an unprecedented pace, with quick turn injection molding standing out as a crucial innovation set to reshape the industry by 2025. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach $365 billion by 2025, driven by the demand for rapid prototyping and cost-effective production solutions. Quick turn injection molding, in particular, allows manufacturers to significantly reduce lead times and meet the growing needs for customized components across various sectors, including automotive and consumer goods. As the mantra 中国制造,全球共享,品质值得信赖 resonates globally, it becomes evident that advancements in technology, such as automation and smart manufacturing, will empower manufacturers to enhance quality and efficiency, ultimately unlocking the full potential of this transformative process.

The landscape of quick turn injection molding is experiencing a remarkable transformation as we approach 2025. The industry is moving towards greater efficiency and adaptability, fueled by advancements in technology and evolving market demands.

Companies that have traditionally focused on prototyping are now expanding their services to meet the increasing need for full-production capabilities. This shift reflects a broader trend where medical device contract manufacturers and design firms are stepping up to offer comprehensive solutions that align with the fast-paced environment of modern manufacturing.

Companies that have traditionally focused on prototyping are now expanding their services to meet the increasing need for full-production capabilities. This shift reflects a broader trend where medical device contract manufacturers and design firms are stepping up to offer comprehensive solutions that align with the fast-paced environment of modern manufacturing.

As we see at events like MD&M West 2025, the collaboration between suppliers, vendors, and manufacturers is becoming integral to this evolution. The emphasis on agile manufacturing processes enables quicker turnarounds and facilitates innovation in product design and development. With the continuous integration of smart technologies and automation, quick turn injection molding is set to redefine its role within the medical technology sector. These advancements are not just improving production speeds but are also enhancing product quality and customization options, a crucial factor in catering to the diverse needs of clients in the medical field.

The injection molding industry is on the cusp of transformation, driven by groundbreaking technologies that are poised to shape its future. A recent report by MarketWatch forecasts that the global injection molding market will reach over $300 billion by 2025, propelled by advances in automation and materials science. Innovative techniques, such as 3D printing integrated with injection molding, are streamlining production processes and reducing lead times, enhancing overall efficiency. By enabling designers to create complex geometries, these technologies allow manufacturers to optimize their resources and minimize waste.

Moreover, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into injection molding machines is revolutionizing production lines. According to a study by Research and Markets, smart injection molding machines are expected to account for more than 25% of the market share by 2025. These machines offer predictive maintenance and real-time monitoring, which not only reduce downtime but also ensure consistent quality in output. As industries explore sustainable practices, advancements in bioplastics and eco-friendly materials are also gaining traction, highlighting a significant shift towards more sustainable manufacturing methods. This multi-pronged approach to technological advancement not only improves efficiency but also positions the injection molding sector as a critical player in the evolving manufacturing landscape.

As the quick turn injection molding industry evolves, quality assurance remains a cornerstone of effective production. Recent advancements highlight the importance of not only speed but also precision and reliability in manufacturing processes. According to a report by MarketsandMarkets, the global market for injection molding is projected to reach $252.8 billion by 2025, driven by increasing demand across sectors such as automotive, consumer goods, and medical devices. This projected growth underscores the necessity for manufacturers to focus on quality assurance systems that can handle rapid production cycles without compromising on product integrity.

In light of recent investments in technology, such as a $3 million expansion to enhance capabilities in mold production, companies must prioritize implementing robust quality control measures. These measures include advanced testing protocols and real-time monitoring systems, which can significantly minimize defects and rework rates. A study from the International Journal of Advanced Manufacturing Technology suggests that effective quality management can reduce defects by up to 50%, highlighting its critical role in maintaining competitiveness within the quick turn injection molding landscape. As the industry navigates technological advancements, the commitment to quality assurance will determine not just survival but success in an increasingly demanding marketplace.

China is emerging as a dominant force in quick turn injection molding, positioning itself as a leader in this rapidly evolving industry. According to a report by ResearchAndMarkets, the global quick turn injection molding market is expected to grow at a CAGR of 8.2% through 2025, with China playing a pivotal role in this expansion. The country's advanced manufacturing capabilities, coupled with its robust supply chain, enable it to efficiently meet the increasing demand for rapid prototyping and production.

With manufacturers in China adopting cutting-edge technologies like automation and artificial intelligence, they are enhancing their production speed and quality. This technological advancement is not only beneficial for domestic companies but also solidifies China's status as a key exporter of quick turn solutions. In fact, the China Plastics Processing Industry Association noted that in 2022, China accounted for about 35% of the global exports of plastic products, showcasing its significant impact on the market. As firms around the world look for faster and more cost-effective manufacturing solutions, China's role in quick turn injection molding is likely to become even more pronounced in the coming years.

| Year | Technology Advancement | Production Capacity (Units) | Export Volume (Million USD) | Market Share (%) |

|---|---|---|---|---|

| 2021 | 3D Printing Integration | 500,000 | 100 | 30 |

| 2022 | AI Optimization | 600,000 | 120 | 35 |

| 2023 | IoT Integration | 700,000 | 150 | 40 |

| 2024 | Sustainable Materials | 800,000 | 180 | 45 |

| 2025 | Advanced Robotics | 900,000 | 200 | 50 |

Sustainability in injection molding is set to transform the industry by 2025, as manufacturers increasingly adopt eco-friendly practices. According to a report by the Plastics Industry Association, the demand for sustainable plastic manufacturing solutions is projected to rise by over 60% in the next two years. This shift is driven by both regulatory pressures and consumer preference for greener products. Injection molding companies are now exploring alternatives, such as bioplastics and recycling technologies, to minimize their environmental footprint.

Moreover, advancements in energy-efficient machinery and automated systems are crucial in reducing waste and improving production efficiency. The Global Plastics Council indicates that using advanced injection molding techniques can cut energy consumption by up to 40%, significantly lowering emissions associated with traditional methods. Emphasizing the use of recycled materials not only meets market demand but also supports circular economy initiatives. As the industry prioritizes sustainability, companies that invest in these technologies will position themselves for success and contribute to a healthier planet.

This chart shows the projected increase in sustainability practices within injection molding from 2019 to 2025. As we move towards 2025, it is expected that the industry's commitment to sustainable practices will significantly rise, indicating a positive trend towards eco-friendliness and efficiency in manufacturing.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |