The evolution of product design has significantly transformed with the integration of plastic prototypes in modern manufacturing. In recent years, the adoption of advanced prototyping technologies has surged, with reports indicating that the global prototyping market is expected to reach $24 billion by 2025. Plastic prototypes play a pivotal role in this growth, allowing designers to rapidly iterate and test their concepts before committing to full-scale production.

The versatility of plastic materials facilitates not only the visualization of ideas but also the optimization of functionality and cost-efficiency. Moreover, industry studies show that companies utilizing plastic prototypes can reduce product development times by up to 30%, thus enhancing their competitive edge in a rapidly evolving market. As manufacturers continue to embrace innovation, the future of product design will undoubtedly be shaped by these advanced prototyping techniques, driving creativity and precision in creating products that meet the demands of consumers.

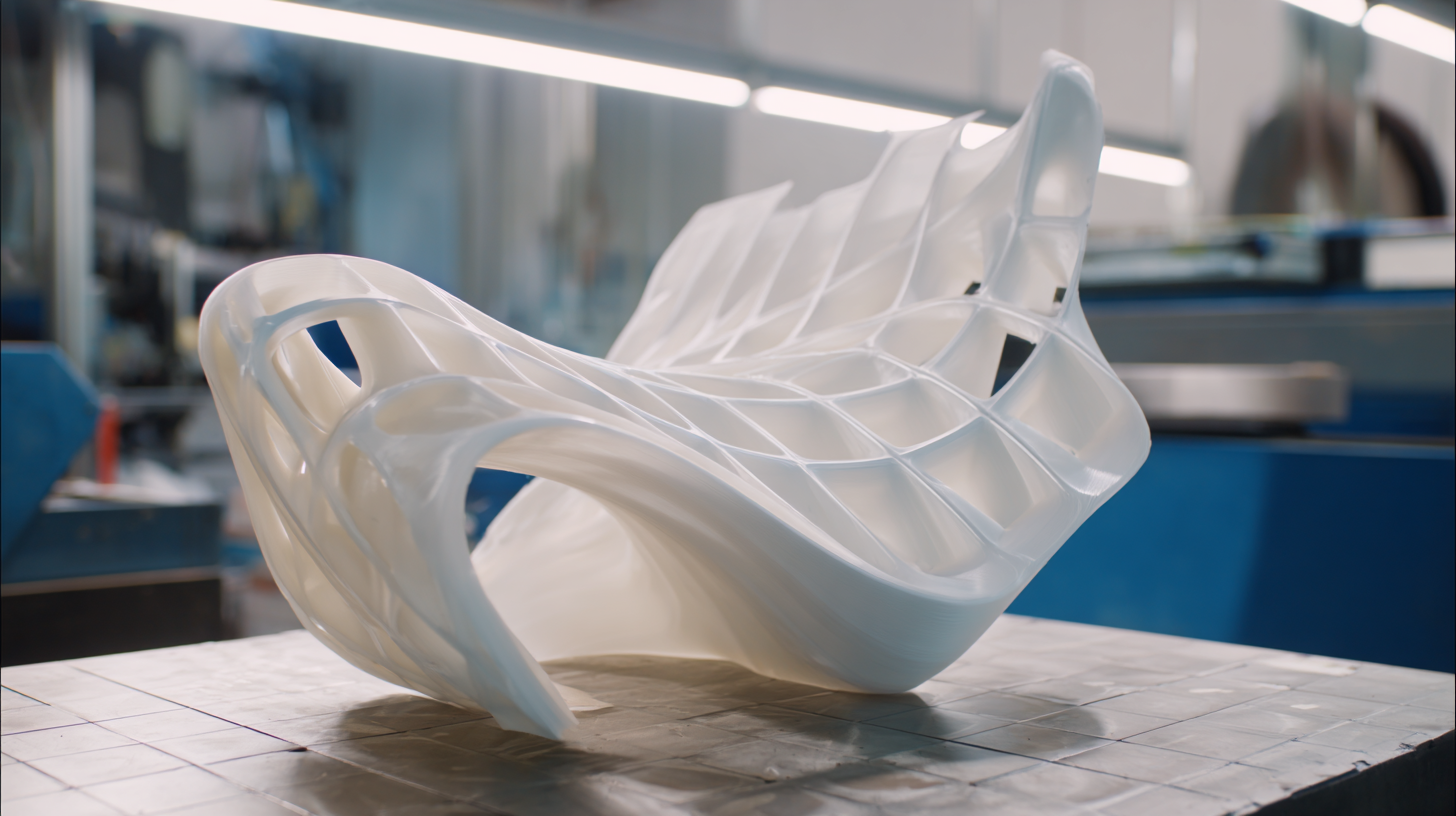

In contemporary manufacturing, plastic prototypes are pivotal in the realm of innovative product design. They serve as tangible representations of abstract concepts, allowing designers to visualize and manipulate their ideas before moving into full-scale production. Through the use of plastic materials, creators can test form, function, and aesthetics, ensuring that the final product aligns with both user expectations and market demands.

Moreover, the flexibility and rapid prototyping capabilities offered by plastic allow for quick iterations in the design process. This agility facilitates feedback loops between designers and stakeholders, enabling teams to identify potential issues early. The reduced lead time associated with plastic prototyping not only accelerates the overall development cycle but also significantly cuts costs, making it an attractive option for companies aiming to innovate while maximizing efficiency. As product design continues to evolve, understanding and leveraging the role of plastic prototypes will be essential in harnessing creativity and bringing groundbreaking ideas to life.

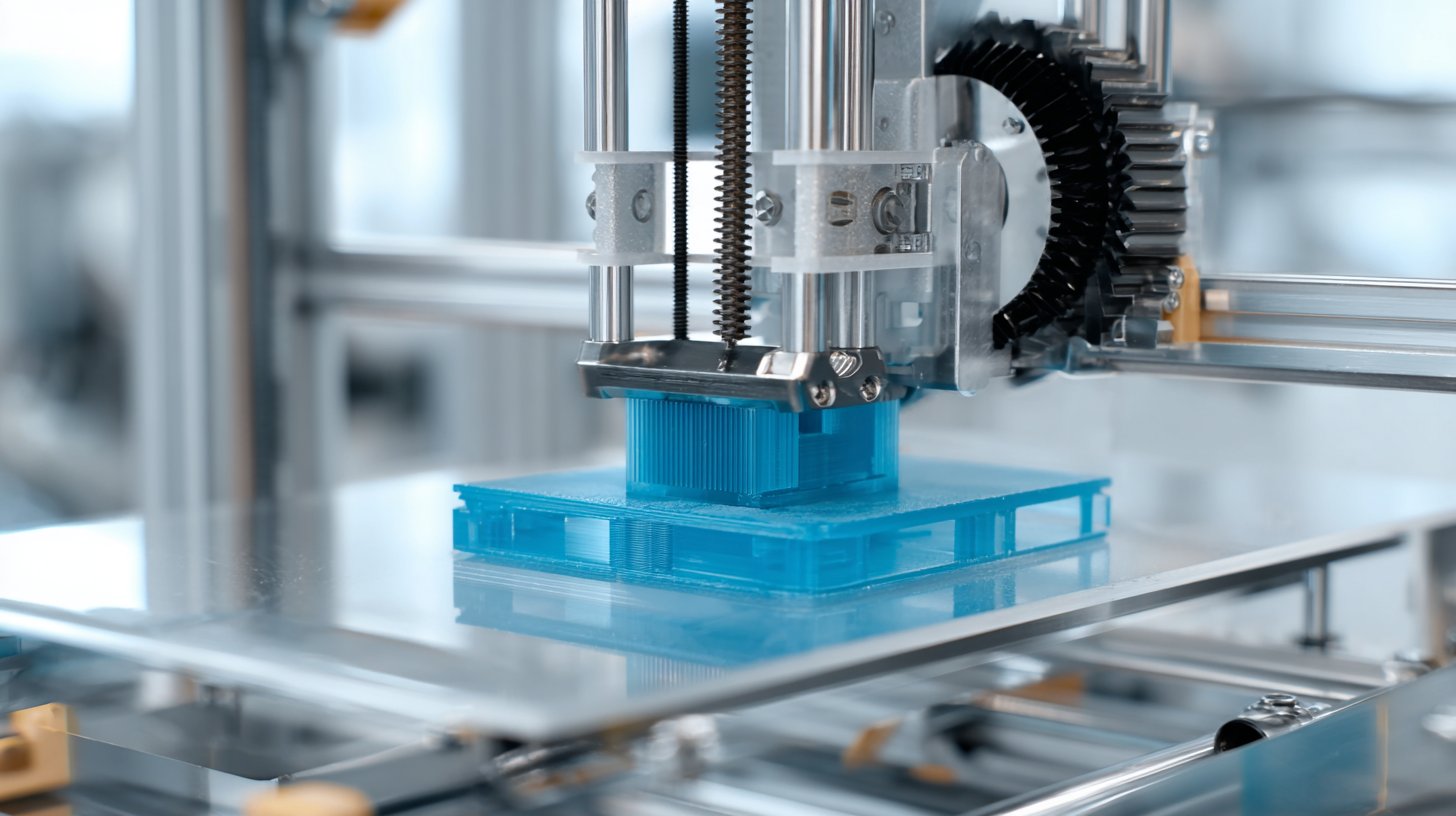

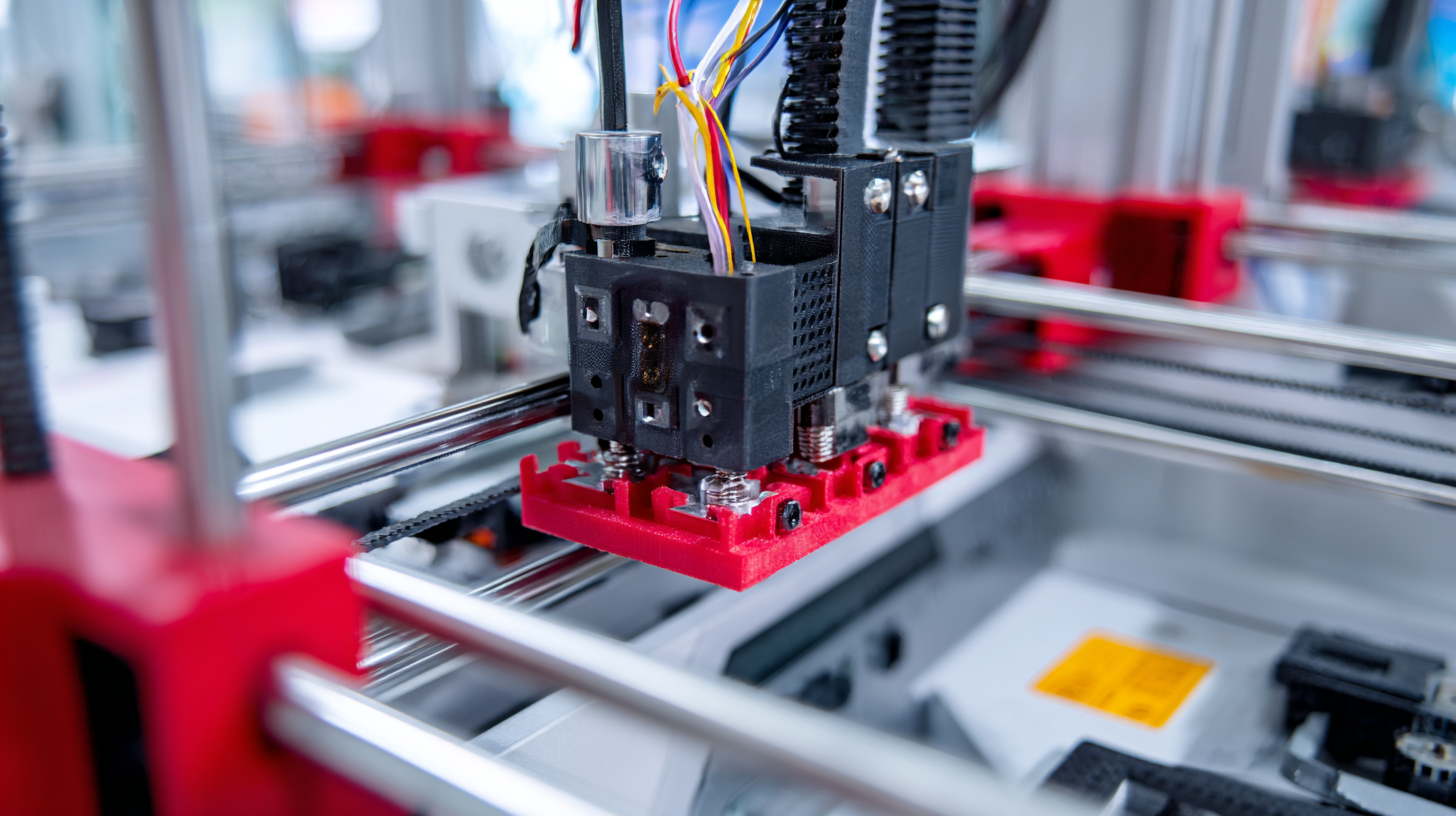

In modern manufacturing, the transition to using plastic prototypes signifies a transformative approach that enhances efficiency and sustainability. One of the key benefits of utilizing plastic prototypes lies in the rapid iteration cycle they enable. By leveraging advanced technologies such as 3D printing and CNC machining, engineers are able to quickly produce prototypes that are not only cost-effective but also environmentally friendly. This speed allows for immediate adjustments based on testing and feedback, significantly reducing the time required to bring products to market.

Moreover, plastic prototypes offer unparalleled flexibility in design. With the growing demand for customized solutions, manufacturers can experiment with various designs without incurring substantial costs or waste. This adaptability is paramount in industries that prioritize sustainability, as it aligns with the latest trends towards responsible manufacturing practices. By ensuring that prototypes accurately reflect the final product, manufacturers can enhance the accuracy of their designs, minimize material waste, and meet the evolving expectations of consumers and stakeholders alike.

Creating effective plastic prototypes is a critical step in modern manufacturing, particularly as industries strive for efficiency and innovation. According to a report by Wohlers Associates, the additive manufacturing market, which includes plastic prototyping, is expected to reach $35.6 billion by 2025. This explosive growth underscores the importance of mastering prototype development for designers and engineers alike.

To begin the prototyping process, it’s crucial to define the product's specifications and requirements clearly. A well-defined scope helps avoid costly revisions later in the development stage. Utilize computer-aided design (CAD) software to create detailed models, as 70% of successful product launches attribute their success to thorough design iterations, as noted by McKinsey & Company.

**Tips:** Always test your prototypes in real-world scenarios to gather feedback early. Consider leveraging 3D printing technology, which can reduce prototype lead time by up to 90%. Lastly, involve cross-functional teams in the prototyping phase to ensure that perspectives from different departments contribute to the prototype’s effectiveness, enhancing overall design quality.

This bar chart demonstrates the projected growth in the production of plastic prototypes from 2020 to 2024, highlighting the increasing importance of plastic prototypes in modern product design and manufacturing processes.

Integrating plastic prototyping into your design workflow can revolutionize your product development process. One of the best practices is to adopt a collaborative approach that encourages input from all stakeholders early in the design phase. This ensures that feedback from engineers, designers, and marketing teams is taken into account, leading to a more refined prototype that meets user expectations and market demands.

Another crucial practice is embracing iterative testing. Utilize rapid prototyping techniques to create multiple versions of the product quickly. By doing so, teams can evaluate and modify designs based on real-world testing and user feedback, enhancing the final product's quality. Moreover, leveraging advanced technologies such as 3D printing within your workflow allows for cost-effective adjustments, enabling teams to innovate without the constraints of traditional manufacturing timelines.

In the rapidly evolving landscape of product design, plastic prototyping has emerged as a fundamental strategy in modern manufacturing. Companies are increasingly recognizing the value of rapid prototyping techniques, which allow them to visualize, test, and iterate designs with speed and accuracy. This not only shortens development cycles but also reduces costs, enabling businesses to respond promptly to market demands and client feedback.

**Tips for Successful Plastic Prototyping:**

- Start with comprehensive planning: Before diving into prototyping, outline your product goals and the features you want to test. A clear vision will streamline the prototyping process.

- Embrace iterative feedback: Involve stakeholders and potential users in the testing phase. Collecting diverse feedback will provide insights that enhance design effectiveness.

- Leverage advanced technologies: Utilize 3D printing and computer-aided design (CAD) to experiment with complex geometries and materials, enhancing the functionality and aesthetic appeal of your prototypes.

The future trends in plastic prototyping are also leaning toward sustainability. As consumers demand eco-friendly products, designers are exploring biodegradable plastics and recycled materials, integrating sustainable practices into product development strategies. Such innovations not only appeal to environmentally conscious customers but also align with global efforts to reduce plastic waste in manufacturing.

| Trend | Description | Benefits | Implementation Challenge |

|---|---|---|---|

| 3D Printing | Use of additive manufacturing for creating prototypes. | Faster production time, cost-effective for low volume. | Need for skilled technicians and equipment investment. |

| Sustainability | Focus on using recyclable and biodegradable materials. | Improves brand image and reduces environmental impact. | Higher costs and limited material availability. |

| User-Centered Design | Prototyping based on user feedback and experiences. | Leads to better product usability and satisfaction. | Potential for conflicting feedback and scope creep. |

| Digital Twin Technology | Creating a virtual prototype to simulate performance. | Allows for testing and iteration without physical limits. | Requires significant technical know-how and software investment. |

| Collaborative Prototyping | Involves multiple stakeholders in the prototyping process. | Enhances innovation through diverse perspectives. | Coordination and communication can be challenging. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |