The advancement of CNC prototyping techniques has revolutionized the landscape of innovation across various industries, from automotive to medical devices. According to a report by Grand View Research, the global rapid prototyping market is expected to reach USD 1.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 12.6% from 2019 to 2026. This significant growth underscores the critical role of CNC prototyping in transforming ideas into tangible products swiftly and cost-effectively.

As companies face increasing pressure to bring products to market faster without compromising quality, CNC prototyping emerges as a vital tool that streamlines the design and manufacturing process. A survey by Wohlers Associates noted that 52% of manufacturers already utilize additive and CNC prototyping technologies to enhance their product development cycles. By leveraging these advanced techniques, organizations not only improve their operational efficiency but also foster a culture of innovation, enabling them to stay ahead in a competitive environment.

Verifying concepts through rapid and precise machining allows businesses to test functionality and design nuances early in the development stage, significantly reducing the risk of costly errors later on. As we delve deeper into understanding CNC prototyping, it becomes clear that this technology is pivotal in unlocking the future of innovation, enabling businesses to respond dynamically to market demands and technological advancements.

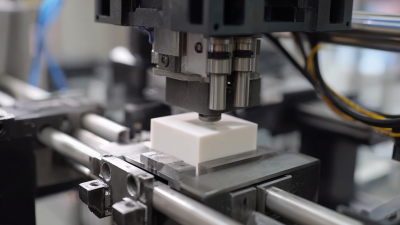

The landscape of product development is being transformed by emerging CNC prototyping techniques that enhance efficiency and precision across various industries. As companies adopt these innovative digital manufacturing methods, the ability to rapidly produce prototypes has led to shorter development cycles, allowing organizations to bring products to market quicker than ever before. The integration of advanced CNC machining enables the production of complex designs with exceptional accuracy, minimizing waste and optimizing material usage.

Recent initiatives, such as the establishment of rapid prototyping labs and new technology centers, exemplify the commitment to fostering innovation. These facilities provide valuable resources for startups and established businesses alike, facilitating collaboration and knowledge sharing. The focus on CNC technology not only boosts productivity but also drives advancements in areas like aerospace and automotive manufacturing, making it an essential component of modern engineering practices. As these techniques continue to evolve, we can expect to see even greater impacts on how products are designed and developed, reshaping the future of innovation.

CNC prototyping techniques have transformed the manufacturing landscape by significantly reducing lead times, with industry reports indicating a reduction of up to 75%. This dramatic efficiency boost stems from the automation and precision that CNC (Computer Numerical Control) machining offers. According to a recent study by Deloitte, manufacturers employing CNC prototyping have reported shortened product development cycles, allowing for quicker iterations and adaptations in response to market demands. The technology's capability to produce complex geometries with minimal human intervention not only accelerates the process but also enhances consistency and quality.

Furthermore, the adoption of CNC prototyping plays a crucial role in streamlining supply chain operations. A survey conducted by PwC revealed that companies leveraging advanced manufacturing technologies, including CNC prototyping, can reduce overall production costs by up to 30% while improving time-to-market. The ability to rapidly prototype and test new products enables businesses to remain agile and competitive in an ever-evolving market. As industries continue to embrace digital transformation, CNC prototyping is poised to remain at the forefront, redefining innovation and operational efficiency across various sectors.

CNC prototyping techniques are revolutionizing the manufacturing landscape, with significant impact on production costs. As industries like automotive and electronics leverage advanced technologies, reports indicate that CNC prototyping can drive up to 40% cost savings. This is particularly crucial as manufacturers adopt digital solutions, moving toward Industry 4.0, where integration of digital twins enhances precision and efficiency. By merging the physical and digital realms, companies can ensure their products are right the first time, streamlining operations and minimizing waste.

Tips for Maximizing CNC Prototyping Benefits:

1. Invest in training your workforce on CNC technology to improve operational efficiency.

2. Consider adopting AI-driven solutions to further enhance precision and reduce production costs.

3. Stay updated on industry trends to ensure your techniques align with market demands.

As China strides towards becoming a leader in CNC innovation, overcoming technological restrictions remains vital for the industry. The anticipated growth in the CNC machine market, projected at a CAGR of 5.5%, underscores the importance of keeping pace with these advancements. Embracing intelligent automation and robotics will not only address existing bottlenecks but also drive future innovations in manufacturing.

The landscape of CNC prototyping is rapidly evolving, driven by the introduction of innovative materials that broaden design possibilities. According to a recent report by SmarTech Analysis, the market for advanced materials in CNC prototyping is projected to grow significantly, with an estimated CAGR of 22.5% over the next five years. Materials such as carbon fiber composites, thermoplastics, and bio-based materials are becoming increasingly popular, enabling designers to explore new dimensions of creativity and functionality.

Additionally, the integration of these materials allows for enhanced durability and performance. For instance, carbon fiber not only offers exceptional strength-to-weight ratio but also presents unique design opportunities that traditional materials cannot match. This trend is essential for industries ranging from aerospace to automotive, where lightweight, high-performance components are critical.

Tip: When selecting materials for CNC prototyping, consider your project's specific requirements such as weight, strength, and environmental factors. This can help you choose the most suitable material for your design, ensuring optimal performance and durability.

Incorporating innovative materials also opens up avenues for sustainable design practices. The rise of bio-based materials, which offer lower environmental impact compared to conventional plastics, is an exciting development in the sector. By adopting these materials, designers not only meet performance standards but also support eco-friendly manufacturing processes.

Tip: Keep up with industry trends and material advancements by attending trade shows and workshops. Networking with peers can provide valuable insights into emerging materials that may enhance your design capabilities.

In recent years, CNC prototyping has emerged as a pivotal component in advancing sustainable manufacturing practices. According to a report by the International Organization for Standardization (ISO), the adoption of CNC technology can reduce material waste by up to 30%, significantly influencing the efficiency of production processes. This is particularly important in a world grappling with the challenges of resource depletion and environmental conservation. By utilizing precise machining techniques, manufacturers can maximize material usage and minimize scrap, leading to both economic and ecological benefits.

Moreover, as industries strive to meet stringent regulations regarding sustainability, CNC prototyping plays a critical role in facilitating the development of eco-friendly products. A study conducted by Mordor Intelligence indicates that the global CNC machining market is projected to reach $100 billion by 2025, emphasizing the growing recognition of its impact on sustainable practices. By integrating renewable materials and employing advanced CNC technologies, businesses can innovate while adhering to social and environmental standards, consequently driving the shift toward a more sustainable future—one where innovation and responsibility go hand in hand.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |