In today’s fast-paced manufacturing environment, rapid prototyping sheet metal plays a crucial role in product development. Designers face constant pressure to innovate and reduce lead times. Rapid prototyping allows for quick iteration and testing, providing engineers with the flexibility they need. This process not only speeds up production but also enhances creativity.

However, challenges exist. Sheet metal design requires precision and careful planning. Changes made during prototyping can lead to increased costs and longer timelines. It’s essential to strike a balance between speed and accuracy. Misalignment in design goals can create setbacks. Each prototype might reveal flaws that demand thoughtful adjustments.

Effective techniques are key to overcoming these hurdles. Utilizing digital tools can streamline the design process. Collaboration among teams fosters better communication. Yet, even with these strategies, imperfections can arise. Embracing a mindset of continuous improvement is crucial for success in rapid prototyping sheet metal.

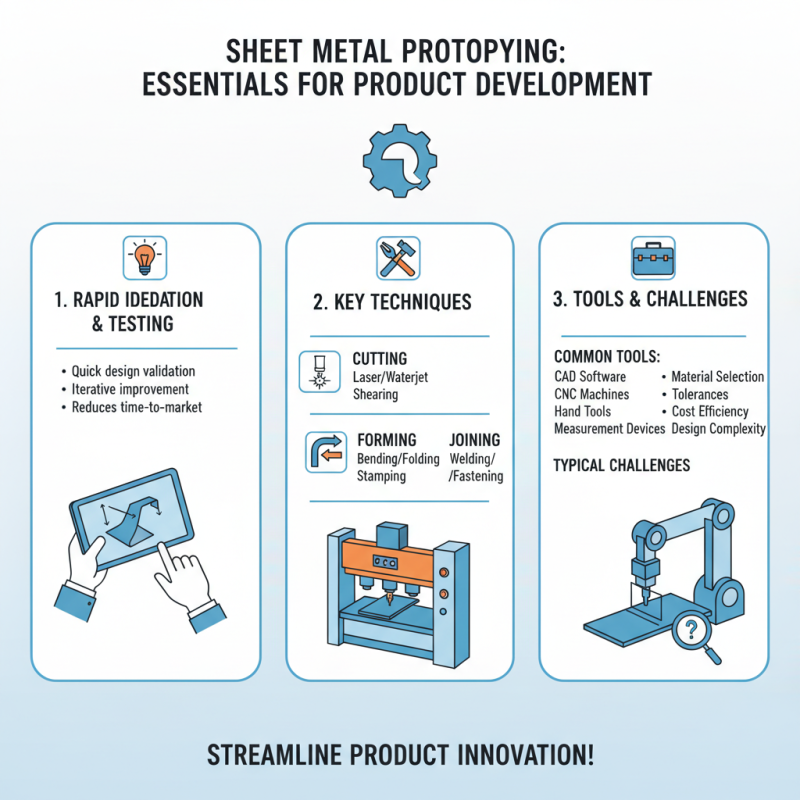

Sheet metal prototyping is an essential aspect of product development. It allows designers to test ideas quickly. Understanding the basic techniques can help streamline the process. Prototyping can involve various tools and equipment, often creating unique challenges.

One common method is CNC machining. It offers accuracy but may require complex setups. Some prototypes may not come out as expected. This can lead to wasted materials and time. Sometimes, simpler methods like hand shearing or bending are overlooked. These techniques can yield faster results and often have less upfront cost.

Collaboration between design and engineering teams is crucial. Miscommunication can lead to errors in design intent. It’s vital to have clear specifications. Review and revise the design iteratively. This not only improves the prototype but also enhances overall understanding. Each iteration provides valuable feedback. Embracing imperfections during the prototyping phase can guide successful final products.

When it comes to rapid prototyping of sheet metal, the choice of materials plays a crucial role. Aluminum is often favored for its lightweight and corrosion resistance. It’s easy to machine and can be used for a variety of applications. However, it can be more expensive than other options. Steel is another common choice, known for its strength and durability. It offers a great balance between cost and performance. Yet, it may present challenges in terms of weight and machinability compared to aluminum.

Another interesting material is stainless steel. It's resistant to corrosion and provides a polished finish. However, creating prototypes can be less efficient due to its hardness. Some designers might overlook the option of composite materials, which can combine different properties. These materials, while versatile, can be complex to work with and may not suit every design requirement. It’s important to evaluate the needs of your project against the material's properties. The wrong choice can lead to wasted resources and time. Prototyping is all about testing and refinement, and material selection should not be an afterthought.

Rapid prototyping in sheet metal design is crucial for engineers. Effective prototypes can help identify flaws early. Research shows that approximately 70% of design errors are found during the prototyping stage. This statistic highlights the importance of adhering to essential design principles.

One key principle is material selection. Choosing the right material can dramatically impact the final product. For instance, aluminum is lightweight and easy to work with, while stainless steel offers durability. However, selecting the wrong material can lead to costly redesigns. Prototypes should also focus on manufacturability. Designs that are too complex can confuse production staff, leading to errors. According to a recent industry report, complexity in design increases manufacturing time by 30%.

Another important aspect is tolerances. Ensuring that parts fit together properly is vital in sheet metal design. A report by the American Society of Mechanical Engineers states that prototypes with improper tolerances can fail in functional tests 60% of the time. It's essential to review design dimensions carefully. Furthermore, engineers should use rapid prototyping technologies like 3D printing to visualize and test designs quickly, even if the results are not always perfect. This iterative process encourages continuous improvement and reflection on previous designs.

Rapid prototyping in sheet metal design is essential for innovation. Efficiency can make a significant difference in production cycles. Studies indicate that companies using advanced techniques can reduce prototyping time by 30-40%. One effective method involves using software that simulates metal forming processes. This can lead to fewer physical prototypes, cutting down on material waste and cost.

Moreover, implementing lean manufacturing principles can greatly enhance efficiency. Identifying and eliminating non-value-adding activities may save both time and resources. In a recent industry report, it was found that 60% of engineers experience delays due to unnecessary steps in the design process. This highlights the importance of continuous assessment and adaptation in prototyping strategies.

Real-life projects often reveal imperfections in initial designs. Feedback loops are crucial; they allow teams to refine prototypes based on real-world testing. Rapid prototyping is not just about speed; it's about learning from each iteration. Balancing speed with quality is challenging. Each step must be evaluated for value, which requires a culture of reflection and improvement.

| Design Technique | Efficiency Improvement (%) | Time Reduction (hrs) | Common Applications |

|---|---|---|---|

| Collaborative Design Tools | 30% | 5 | Automotive Parts |

| Simulation Software | 25% | 4 | Industrial Components |

| Advanced Manufacturing Techniques | 40% | 6 | Electronics Housings |

| Rapid Tooling | 35% | 3 | Consumer Goods |

| Iterative Prototyping | 20% | 2 | Medical Devices |

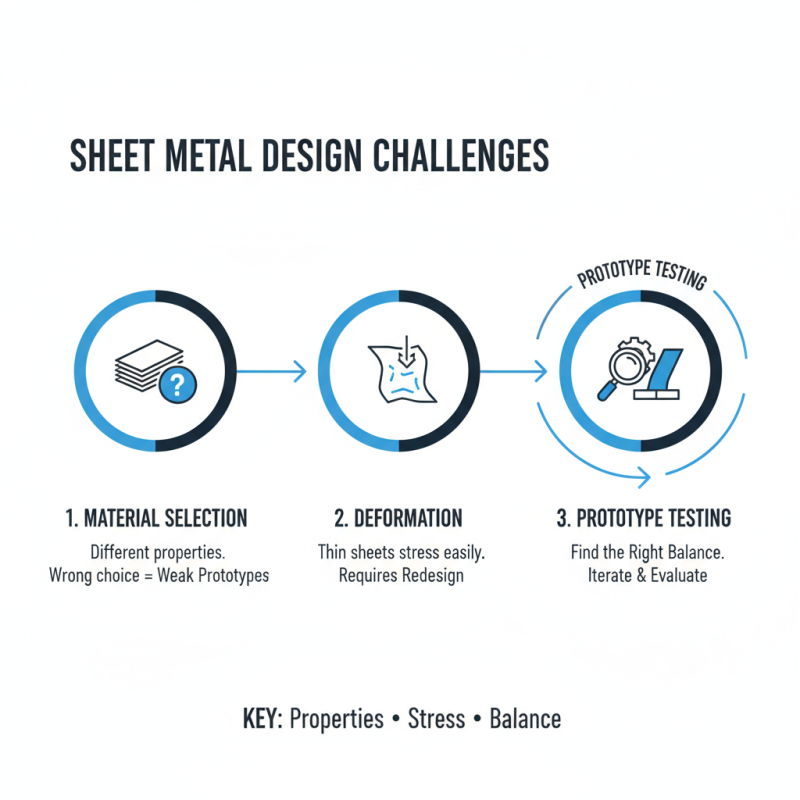

Sheet metal design often brings various challenges. One significant issue is material selection. Different metals have unique properties that affect the design. Choosing the wrong material can lead to weak prototypes. Thin sheets may deform easily under stress. This requires designers to rethink their choices. Testing various materials can help find the right balance.

Another challenge is ensuring accurate measurements. Precision is critical in sheet metal design. Small errors can lead to significant performance issues. Designers must frequently measure and adjust their prototypes. Utilizing digital tools can aid in achieving better accuracy. However, reliance on these tools can introduce new problems. Software glitches may cause unexpected results.

Lastly, production techniques can complicate the process. Techniques like bending, cutting, and welding require specific expertise. Mistakes during these processes can be costly. It's important to collaborate with skilled fabricators. This partnership can improve results but also requires ongoing communication. Regular feedback can identify potential pitfalls early on.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |