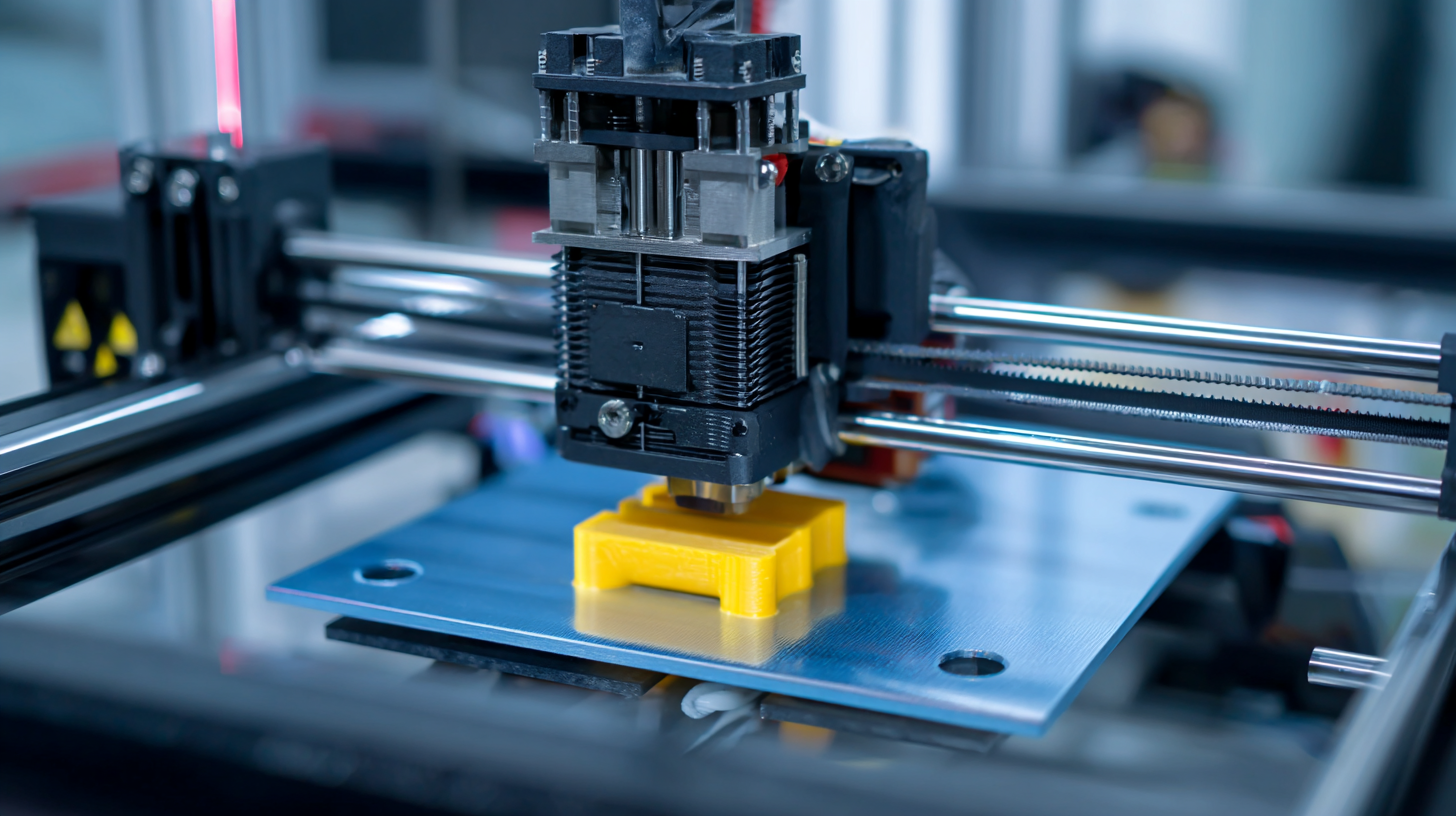

In the rapidly evolving landscape of manufacturing, the demand for 3D printing prototypes has surged, reflecting a significant shift towards more innovative and efficient production methods. According to a report by Wohlers Associates, the 3D printing industry is projected to reach $44.2 billion by 2026, illustrating the technology's critical role in prototyping across various sectors. As companies increasingly rely on 3D printing for rapid prototyping, selecting the right manufacturer becomes essential for ensuring quality, speed, and cost-effectiveness.

This blog will provide a comprehensive comparison of key factors to consider when choosing the best 3D printing prototype manufacturer for your project needs. By understanding these elements, businesses can make informed decisions that align with their goals and enhance their product development processes.

Selecting the right 3D printing prototype manufacturer is critical to the success of any project. With the rapid advancements in the 3D printing industry and the emergence of new technologies, manufacturers vary significantly in their capabilities, expertise, and offerings. A thorough understanding of what each manufacturer specializes in can help you align your project requirements with their strengths. For instance, many manufacturers are increasingly focusing on high-end applications, which presents a unique opportunity for companies to leverage cutting-edge technologies for advanced prototypes.

Recent developments in the 3D printing sector, like the establishment of new production facilities with substantial investments, highlight the growing significance of this technology in various industries. By 2030, the market for 3D printing is expected to reach impressive valuations, illustrating the expanding potential that different sectors, including aerospace and automotive, see in 3D printing. When choosing a manufacturer, consider their latest technological capabilities and track record in delivering high-quality prototypes. This strategic selection will not only enhance the innovation of your project but also ensure that you remain competitive in a rapidly evolving market.

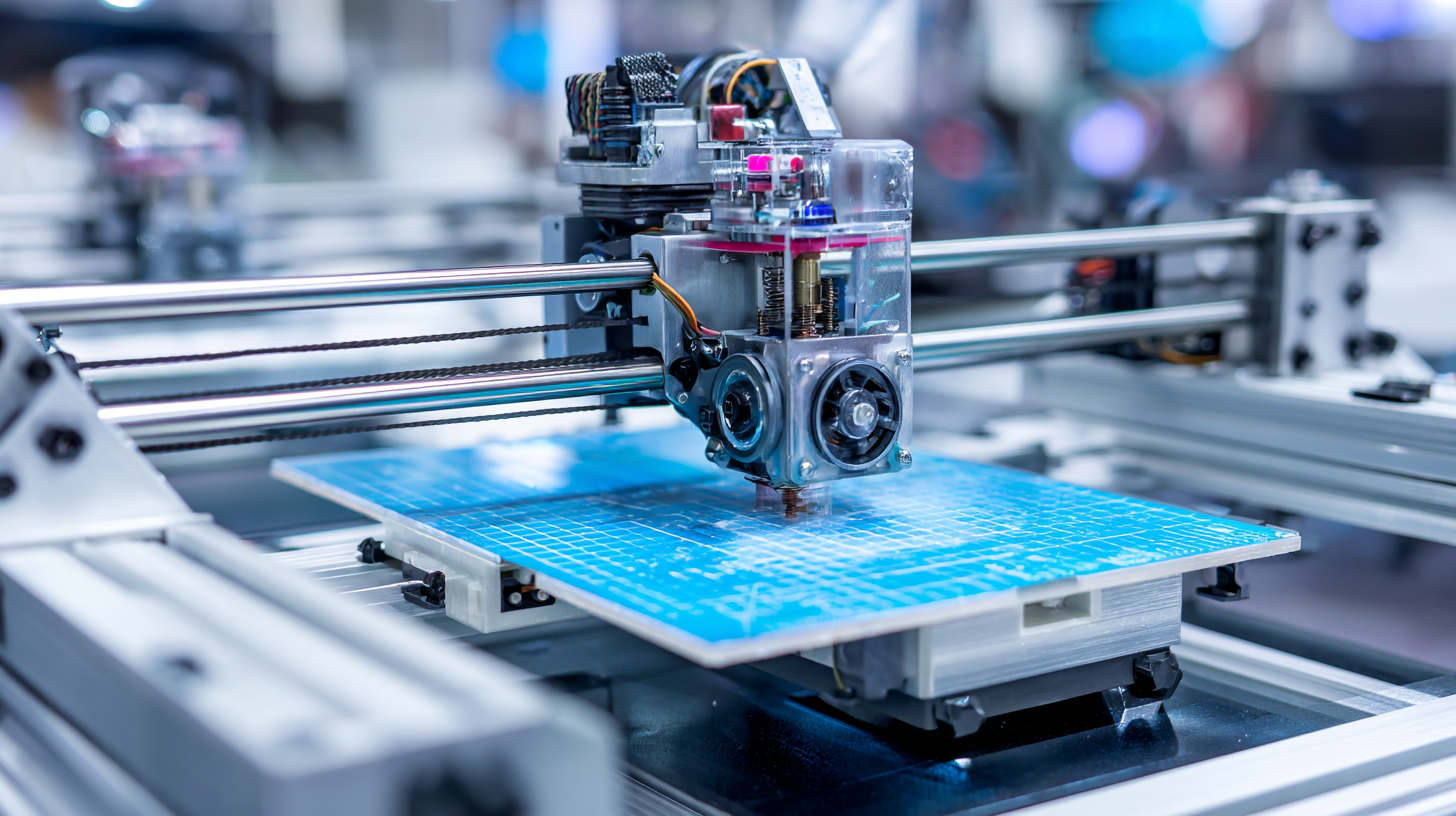

When selecting a 3D printing prototype manufacturer, it’s crucial to evaluate several key factors that can significantly impact the success of your project. First, consider the manufacturer’s expertise and technology. A provider with advanced printing technologies and a range of materials can offer tailored solutions suited for various applications, whether it's product design, modeling, or visualization. Checking their portfolio for previous projects can help you assess their capabilities and ensure they align with your project requirements.

Additionally, turnaround time and production capacity are essential elements to consider. The ability to meet deadlines while maintaining quality standards can determine the efficiency of your development process. Another critical factor is customer support; a responsive and knowledgeable support team can provide valuable assistance throughout the project lifecycle, ensuring a smooth collaboration. As the demand for 3D printing services continues to grow, finding a manufacturer that offers the right balance of technology, capacity, and support will set the foundation for a successful outcome.

The 3D printing industry has seen remarkable growth in recent years, with projections indicating a significant expansion in various segments, including the digital twin market. According to recent analyses, the global digital twin market is expected to soar from $24.48 billion in 2025 to an astonishing $259.32 billion by 2032, reflecting a remarkable compound annual growth rate (CAGR) of 40.1%. This growth is indicative of the increasing integration of advanced technologies into prototyping processes, enabling companies to create more accurate and efficient prototypes within shorter timeframes.

Additionally, the 3D printing eyewear market is also on the rise, with forecasts estimating the market size to grow from approximately $156.27 million in 2025 to around $309.1 million by 2033, showcasing a steady CAGR of 8.9%. This surge is fueled by innovation and customization capabilities provided by 3D printing, allowing manufacturers to meet diverse consumer needs while optimizing production costs.

As these trends continue to evolve, it's clear that the impact of 3D printing on prototyping and beyond will play a crucial role in shaping the future of manufacturing.

When selecting a 3D printing prototype manufacturer, understanding the comparative costs associated with different pricing models is crucial. According to a report by SmarTech Analysis, the average cost of 3D printing services can vary dramatically, ranging from $30 to $300 per hour, depending on the complexity of the project and the technology employed. Manufacturers that utilize advanced materials such as selective laser melting (SLM) or direct metal laser sintering (DMLS) typically charge at the higher end of this spectrum due to the greater costs of materials and equipment.

Furthermore, many manufacturers offer different pricing strategies, including fixed-price contracts, hourly rates, and pricing per cubic inch of printed material. A study conducted by Wohlers Associates noted that prototypes made using Fused Deposition Modeling (FDM) might cost between $0.05 to $0.15 per gram of filament used, while more intricate designs using SLS can cost up to $0.30 per gram. As businesses assess their project needs, understanding these divergent cost structures allows for informed budget allocation and helps in selecting a manufacturer that aligns with both performance expectations and financial constraints.

When selecting a 3D printing prototype manufacturer, assessing quality and turnaround time is crucial for the success of your project. According to a recent report by Wohlers Associates, companies that emphasize rapid prototyping can decrease their product development cycle by up to 60%, making it essential to partner with a manufacturer that prioritizes quick delivery without compromising quality. Metrics such as average lead time, production capabilities, and the quality assurance processes in place are vital indicators of a manufacturer’s reliability.

Tip: Always inquire about the manufacturer's specific turnaround time benchmarks. A reputable 3D printing service should be transparent about their timelines and provide estimates based on your project requirements. Additionally, look for services that utilize advanced technology, such as multi-material printers, which can significantly enhance prototype quality and functionality.

Moreover, understanding the quality control measures of a manufacturer is critical. A survey by the Additive Manufacturing Users Group indicated that 74% of businesses cited quality assurance as a top priority when selecting a prototyping partner. Ensure that the manufacturer implements rigorous testing and evaluation protocols to deliver prototypes that meet industry standards and your project specifications.

Tip: Requesting samples of previous work can give you a clear understanding of their quality capabilities, helping you make an informed decision.

| Manufacturer Type | Quality Rating (1-5) | Average Turnaround Time (Days) | Materials Offered | Post-Processing Services |

|---|---|---|---|---|

| FDM 3D Printing | 4 | 7 | PLA, ABS, PETG | Sanding, Painting |

| SLA 3D Printing | 5 | 5 | Standard Resin, Tough Resin | Polishing, Coating |

| SLS 3D Printing | 4.5 | 10 | Nylon, TPU | Dyeing, Finishing |

| Metal 3D Printing | 4.8 | 14 | Stainless Steel, Aluminum | Machining, Surface Treatment |

| Multi Jet Fusion | 4.7 | 9 | Nylon, PA12 | Texturing, Coloring |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |