In the rapidly evolving landscape of manufacturing, low volume injection moulding has emerged as a critical process for companies seeking to produce high-quality parts with reduced waste and greater efficiency. According to a report by MarketsandMarkets, the global injection moulding market is projected to reach $341.5 billion by 2025, highlighting the increasing demand for tailored solutions in niche applications. However, low volume injection moulding poses unique challenges, including increased per-part costs, longer lead times, and limitations in design complexity. As industries from automotive to consumer electronics push for innovation and customization, understanding these obstacles and exploring viable alternatives becomes essential.

This blog will delve into the insights and solutions available to address the challenges of low volume injection moulding, providing manufacturers with the tools they need to thrive in a competitive market.

Low volume injection moulding (LVIM) has emerged as a vital process for manufacturers looking to produce parts with sensitivity to cost and time. A recent report from Grand View Research indicates that the global low volume injection moulding market is expected to reach USD 4.4 billion by 2027, growing at a CAGR of 7.1%. This growth is driven by the increasing demand for rapid prototyping and custom components across various industries, including automotive, healthcare, and consumer goods. Companies are increasingly adopting LVIM to reduce lead times and cater to small batch production efficiently.

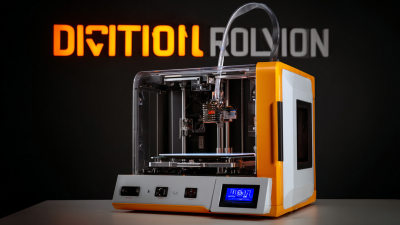

Market trends indicate that advancements in materials and technology are further propelling the LVIM sector. For instance, according to a study by ResearchAndMarkets, the adoption of sustainable materials and eco-friendly processes is becoming a priority as manufacturers strive to meet stringent regulatory requirements. Additionally, with 3D printing technologies enhancing design flexibility, businesses are more inclined to utilize LVIM for intricate designs that were previously cost-prohibitive. As manufacturers continue to adapt to these trends, the future of low volume injection moulding appears promising, showcasing its potential to revolutionize production practices across multiple sectors.

Low volume injection moulding presents unique challenges, particularly concerning quality control and consistency. According to a report by Grand View Research, the global injection moulding market is expected to reach USD 350 billion by 2025, emphasizing the growing demand for high-quality components across various sectors. However, maintaining consistency in low volume runs remains a critical issue. With production volumes often falling below 10,000 units, small variations in the injection process can significantly impact the final product's quality.

Low volume injection moulding presents unique challenges, particularly concerning quality control and consistency. According to a report by Grand View Research, the global injection moulding market is expected to reach USD 350 billion by 2025, emphasizing the growing demand for high-quality components across various sectors. However, maintaining consistency in low volume runs remains a critical issue. With production volumes often falling below 10,000 units, small variations in the injection process can significantly impact the final product's quality.

One of the main hurdles is the control of temperature and pressure during the injection cycle, which can lead to defects like warping or incomplete filling. A study published in the Journal of Manufacturing Science and Engineering reveals that even a 5% deviation in these parameters can result in a 30% increase in defects. Implementing advanced monitoring systems and utilizing machine learning algorithms can enhance quality control by providing real-time data analysis, enabling manufacturers to adjust parameters instantaneously and minimize inconsistencies. As companies adapt to meet consumer demands for customized solutions, prioritizing these technical advancements is crucial for ensuring product reliability and trust in low volume injection moulding practices.

In today's manufacturing landscape, low volume injection moulding presents unique challenges that require innovative solutions. To effectively address these hurdles, leveraging advanced technologies is crucial. For instance, the adoption of 3D printing in the prototyping phase allows designers to create and test intricate designs quickly and affordably. This not only reduces time-to-market but also enables the fine-tuning of product specifications before committing to expensive mould production.

Another significant advancement is the use of state-of-the-art simulation software, which allows manufacturers to predict potential issues in the injection moulding process. By simulating the flow of materials and the behaviour of moulded parts under various conditions, companies can proactively identify design flaws and optimize parameters for better efficiency and quality. Integrating these technologies leads to improved precision in low volume production, ensuring that products meet specifications while minimizing waste and costs. As the industry continues to evolve, the adoption of such technologies will be vital in overcoming the inherent challenges of low volume injection moulding.

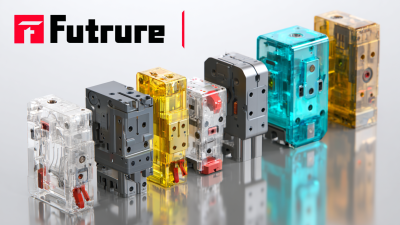

When it comes to low volume injection moulding, selecting the right materials is crucial for optimizing performance and ensuring the final product meets quality standards. One effective strategy involves leveraging engineering-grade plastics, which not only boast superior mechanical properties but also offer enhanced thermal stability. Materials such as polycarbonate or nylon are excellent candidates, as they provide the durability required in various applications while maintaining flexibility during manufacturing. Understanding the specific requirements of the end-use application helps in making informed decisions about material selection.

Another significant consideration is the compatibility of the chosen materials with the injection moulding process. It's important to evaluate factors such as melt flow rate and processing temperature, as these can impact the quality and consistency of the parts produced. Utilizing additives or fillers can further enhance the properties of the base materials, allowing for tailored solutions that address specific performance needs. By combining the right materials with best practices in processing, manufacturers can overcome the challenges associated with low volume production, ultimately leading to better product outcomes and client satisfaction.

Low volume injection moulding has emerged as a strategic alternative for many manufacturers seeking to balance cost with efficiency. When conducting a cost-benefit analysis, one must consider not only the initial tooling costs associated with traditional methods but also the long-term benefits that low volume techniques provide. Low volume injection moulding often involves lower setup costs and reduced lead times, making it an attractive option for businesses that require flexibility in production without committing to large quantities.

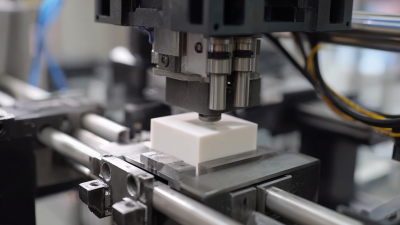

One of the critical advancements in enhancing the efficiency of low volume injection moulding is the integration of conformal cooling channels (CCCs). These specialized cooling channels are designed to maintain an even distance from the mold surface, significantly improving the cooling rate. This optimization of process parameters ensures that the plastic solidifies uniformly, reducing cycle times and enhancing the quality of the finished parts. Additionally, recent innovations in direct metal printing for injection moulds, which utilize advanced cooling channel designs, have demonstrated a noticeable decrease in coolant leakage and overall enhanced thermal management, amplifying the efficiency and cost-effectiveness of low volume production methods.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |