In the fast-paced world of product development, speed often outweighs perfection. Rapid 3D printing has emerged as a game-changer for prototyping, allowing designers to quickly iterate their ideas. As industry expert Dr. James Harper once said, "The art of making mistakes is crucial; it leads to innovation." This mindset is vital in the realm of rapid 3D printing.

Prototyping is no longer a lengthy process. With techniques like digital light processing and selective laser sintering, designers can produce models in a fraction of the time. This technology allows for faster feedback, leading to quicker improvements. Nevertheless, the speed of rapid 3D printing sometimes compromises the fine details. Balancing speed with quality is an ongoing challenge.

There are numerous techniques available for rapid 3D printing. Each method has its strengths and weaknesses. Designers must choose what best fits their needs. In some cases, rapid results may lead to oversight. It is essential to reflect on the importance of detail while embracing the speed of innovation. Rapid 3D printing is reshaping the prototyping landscape, and finding the right balance is key to success.

Rapid 3D printing techniques are changing the way prototypes are developed. These methods allow creators to turn ideas into tangible models quickly. Each technique has its strengths and weaknesses. Understanding these is crucial for effective prototyping.

One popular method is Fused Deposition Modeling (FDM). It works by stacking layers of material. It’s easy to use but often lacks fine detail. Another effective approach is Stereolithography (SLA). This method uses UV light to cure resin. It delivers high precision, but the materials can be expensive. There are other techniques like Selective Laser Sintering (SLS), which sinters powdered materials. It’s versatile but can lead to rough surfaces.

Despite the advances, challenges remain. Not all methods can produce strong prototypes. Some require extensive post-processing to achieve a polished look. Designers need to consider the balance between speed and quality. The choice of technique can significantly impact outcomes. Experimentation and feedback are vital in this evolving field.

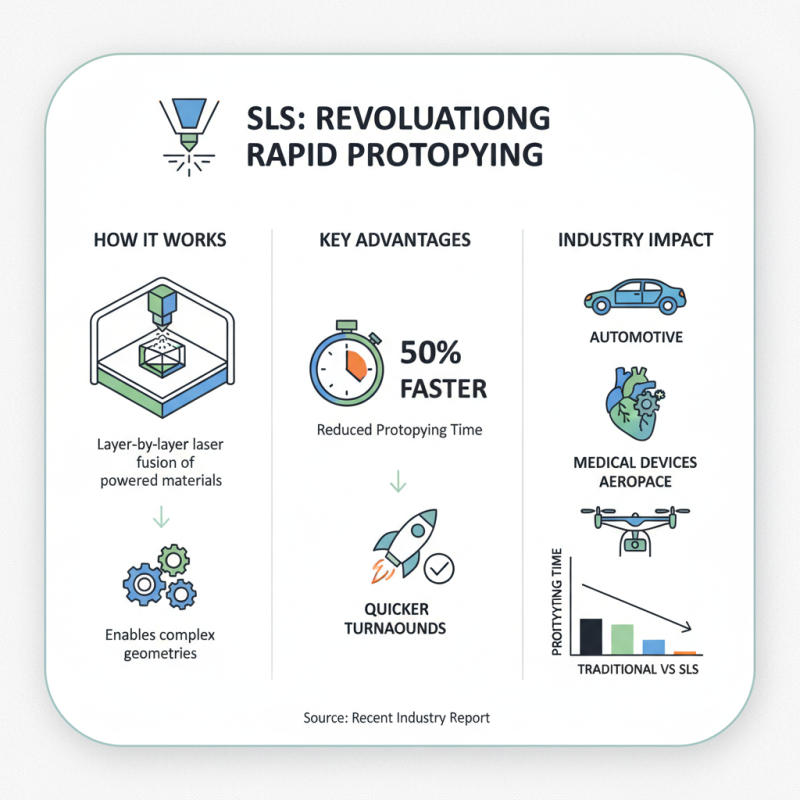

Selective Laser Sintering (SLS) is revolutionizing rapid prototyping. This technique uses a laser to fuse powdered material, layer by layer. It enables the production of complex geometries that traditional methods cannot achieve. In a recent industry report, SLS was found to reduce prototyping time by up to 50% compared to other methods. This is crucial for industries needing quicker turnaround.

Speed is not the only advantage of SLS. It allows for efficient material usage, reducing waste significantly. According to annual data, SLS can utilize up to 90% of the powder used during printing. However, the quality of the final products can vary, especially if the parameters are not properly controlled. Inconsistent layering can lead to weak points in the design.

Moreover, while SLS is fast, it requires skilled operators. Achieving optimal results involves careful calibration and monitoring. There are instances where a machine may malfunction, leading to production delays. As with any technology, it’s essential to weigh speed against the potential for error.

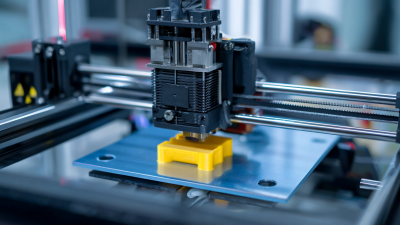

Fused Deposition Modeling (FDM) is one of the most popular 3D printing techniques. It works by melting a thermoplastic filament. This process allows for rapid and cost-effective prototyping. Designers can quickly produce parts that are functional and visually engaging. The ability to create complex geometries is a significant advantage.

However, FDM has its limitations. Print quality can vary based on settings. Layer adhesion may not be as strong as other methods. Intricate details might not translate well, leading to rough surfaces. These issues can affect the final product's usability. It's important to refine designs through iteration. Testing prototypes helps identify flaws early in the process. Effective communication with engineers and designers becomes vital.

While FDM is efficient, it requires ongoing assessment. Balancing speed and quality is challenging. As materials and technology evolve, staying informed is crucial. Each project brings unique demands, compelling users to rethink their approaches. Ultimately, FDM serves as a reliable choice for those willing to adapt and innovate.

Stereolithography (SLA) stands out as a top choice for high-resolution prototyping. This technique uses a laser to cure liquid resin into solid plastic. It can create intricate details that many other methods struggle to achieve. The result is smooth surfaces and fine features, making it a favorite for designers.

One downside of SLA is the post-processing time. After printing, parts need cleaning and curing. This extra step can delay projects. Sometimes, achieving perfect detail means sacrificing speed. Designers often weigh accuracy versus time in their projects.

Another challenge is the material choices. While SLA offers various resins, they can be expensive. Some resins may not be durable enough for end-use products. This limitation can restrict designs or require compromise. Ultimately, SLA remains a valuable tool. However, it's essential to reflect on its limitations and processes before diving in.

Continuous Liquid Interface Production (CLIP) represents a groundbreaking advancement in 3D printing technology. This method utilizes UV light and a photosensitive resin to create objects layer by layer. Reports indicate that CLIP can produce parts up to 100 times faster than traditional techniques. This speed is significant for industries needing rapid prototyping.

However, efficiency comes with challenges. The technology requires precise control of the resin's curing process. Inconsistencies can lead to defects in finished products. A study in the Advanced Materials journal noted that nearly 15% of prototypes had structural flaws due to improper resin handling. The need for continuous monitoring can introduce delays.

Despite these drawbacks, CLIP’s efficiency metrics remain appealing. With a layer thickness as thin as 0.1 mm, it achieves strong detail fidelity. The ability to produce complex geometries in less time reduces labor costs and accelerates product development cycles. Yet, companies must weigh these advantages against potential quality issues. Continuous improvement in handling and quality control can help mitigate these risks.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |