In the fast-paced world of manufacturing, quick turn injection molding has emerged as a critical process for businesses looking to stay competitive. According to a report from Grand View Research, the global injection molding market is expected to reach $341.3 billion by 2025, driven largely by the increasing demand for rapid prototyping and short-run production. This trend underscores the importance of adopting efficient practices to optimize the quick turn injection molding process. Companies that harness the full potential of this method can significantly reduce lead times and costs while maintaining high-quality standards. In this blog, we will explore the five best practices that can enhance the efficiency of quick turn injection molding, enabling manufacturers to meet customer demands effectively and swiftly.

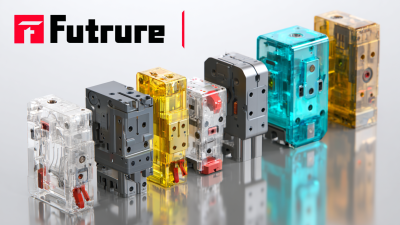

Quick turn injection molding has emerged as a vital manufacturing process, particularly for industries that require rapid product development and market entry. This method allows for reduced lead times and the ability to produce high-quality plastic parts with precision. According to a report by Grand View Research, the global injection molding market is expected to reach $430 billion by 2027, highlighting the increasing demand for efficient production techniques like quick turn molding.

Quick turn injection molding has emerged as a vital manufacturing process, particularly for industries that require rapid product development and market entry. This method allows for reduced lead times and the ability to produce high-quality plastic parts with precision. According to a report by Grand View Research, the global injection molding market is expected to reach $430 billion by 2027, highlighting the increasing demand for efficient production techniques like quick turn molding.

One of the key benefits of quick turn injection molding lies in its ability to facilitate iterative product designs. With the use of advanced technologies and streamlined processes, manufacturers can produce prototypes and small batches within days rather than weeks. This accelerated timeline is crucial for sectors such as automotive and consumer electronics, where time-to-market can significantly impact competitiveness. A study by industry experts found that companies implementing quick turn mold production can see reductions in project timelines by up to 50%, significantly enhancing innovation cycles.

Additionally, applications of quick turn injection molding extend beyond prototyping. Industries like healthcare and aerospace leverage this technique to produce specialized components that meet stringent regulatory requirements while maintaining quick turnaround times. Customization and adaptability are critical, as highlighted in a report by Market Research Future, which suggests that the rapid prototyping market will grow at a CAGR of 25% through 2025. This growth underscores the necessity for industries to adopt quick turn injection molding to stay ahead in an increasingly agile marketplace.

When it comes to quick turn injection molding, optimal material selection plays a critical role in enhancing both performance and cost-effectiveness. The choice of materials not only influences the mechanical properties of the molded parts but also impacts the overall production costs. For instance, materials that exhibit thermal stability and excellent flow characteristics can significantly reduce cycle times and improve dimensional accuracy. Therefore, understanding the specific requirements of the end application is essential when selecting the right material.

Tips for efficient material selection include:

1. Assessing the mechanical and thermal properties required for the application to ensure durability and functionality.

2. Considering the material’s compatibility with the injection molding process to minimize defects and maximize production efficiency.

3. Evaluating cost and availability to balance performance needs with budget constraints.

Moreover, recent advances in material technologies emphasize the importance of selecting innovations that enhance productivity without compromising quality. The integration of modern composites and lightweight materials can further optimize manufacturing capabilities while promoting sustainability in production, thus leading to more cost-effective solutions in quick turn injection molding.

In today’s fast-paced manufacturing environment, reducing lead time is crucial for maintaining a competitive edge. One effective technique is the implementation of advanced planning software that allows for real-time oversight of production workflows. By forecasting demands and scheduling maintenance in advance, manufacturers can minimize downtime, ensuring that the injection molding process runs smoothly and efficiently. This proactive approach not only optimizes the use of resources but also enhances collaboration between teams, leading to quicker decision-making.

Another key practice is the use of modular tooling systems. By designing molds that can be easily reconfigured for different products, manufacturers can significantly reduce changeover times. This flexibility enables rapid shifts in production lines to accommodate urgent orders without sacrificing quality or efficiency. Additionally, investing in training for staff on these systems equips them with the skills needed to adapt to changes swiftly, thereby shortening lead times further and ensuring consistency in output quality.

| Best Practice | Description | Impact on Lead Time | Implementation Difficulty |

|---|---|---|---|

| Design for Manufacturability (DFM) | Incorporating molding requirements during the design phase. | Reduces initial prototype revisions, speeding up the process. | Medium |

| Use of Advanced Materials | Selecting materials that allow for quicker cycle times. | Enhances production speed and efficiency. | Low |

| Optimized Machine Settings | Calibrating machines for optimal performance. | Reduces cycle time and improves part quality. | Medium |

| Parallel Processing | Simultaneous production for multiple parts. | Dramatically cuts down lead time for larger orders. | High |

| Regular Maintenance | Scheduled checks to prevent machine downtime. | Minimizes production delays. | Medium |

Quality control measures are essential in quick turn injection molding to guarantee consistency and precision throughout the production process. Implementing rigorous quality assessment strategies can significantly minimize defects and enhance the performance of the final products. One effective measure is the use of automated inspection systems, which can detect inconsistencies in real-time, allowing for immediate corrective actions. This not only reduces waste but also ensures that each component meets the predetermined specifications.

Another critical aspect of quality control is the establishment of standard operating procedures (SOPs) for every stage of production. By standardizing processes such as material selection, injection parameters, and cooling times, manufacturers can create a controlled environment that fosters repeatability. Additionally, conducting regular training sessions for operators reinforces these SOPs, ensuring that all team members are proficient in best practices. Investing in training and adherence to established protocols enhances overall product reliability, ultimately leading to greater customer satisfaction.

In the fast-paced world of manufacturing, quick turn injection molding has emerged as a vital process for producing high-quality parts in shorter timeframes. Automation plays a crucial role in enhancing the efficiency of this process. By integrating advanced machinery and software solutions, manufacturers can streamline production cycles, minimize manual errors, and improve overall throughput.

Automated systems enable real-time monitoring and adjustments, ensuring that every stage of the molding process operates at optimal performance levels.

Moreover, adopting smart technology in quick turn injection molding allows for better resource management. With predictive analytics and machine learning, manufacturers can forecast potential challenges and make informed decisions to mitigate downtime. The use of robotics in handling materials and parts further accelerates the operation, enabling human workers to focus on more complex tasks that require critical thinking and creativity.

Embracing automation in this sector not only boosts efficiency but also opens avenues for innovation, positioning companies to meet the increasing demands of a competitive market.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |