In today's fast-paced design environment, the demand for innovative and customized solutions is more pressing than ever. Metal prototyping has emerged as a crucial part of this landscape, enabling designers and engineers to bring their creative visions to life with precision and speed. By harnessing the best metal prototyping solutions, businesses can unlock potential not just in their products but also in their overall design processes. This blog delves into top strategies that can enhance the effectiveness of metal prototyping, exploring cutting-edge technologies, materials, and techniques that the industry has to offer. As we navigate through the various methods and applications, you'll discover how leveraging the right prototyping approaches can lead to groundbreaking designs and significant competitive advantages in the market.

In 2025, the landscape of metal prototyping is set to undergo significant transformations driven by technological advancements and innovative practices. One of the most noteworthy trends is the rise of additive manufacturing techniques, specifically Metal 3D Printing, which allows for the creation of complex geometries that were previously unattainable. This approach not only accelerates the prototyping process but also reduces material waste, making it an eco-friendly alternative in the manufacturing industry. As designers and engineers harness these capabilities, we can expect a surge in customized products tailored to meet specific client needs, ensuring that innovative designs can materialize from concept to reality efficiently.

Another important trend to watch is the integration of artificial intelligence and machine learning in the prototyping phase. These technologies enable predictive modeling, which can optimize design parameters and streamline the prototyping workflow. By analyzing vast amounts of data from past projects, AI can suggest improvements in designs and help avoid common pitfalls, ultimately enhancing the quality and functionality of prototypes. As companies embrace these cutting-edge tools, they will not only innovate their products but also significantly shorten the time-to-market, giving them a competitive edge in an increasingly fast-paced environment.

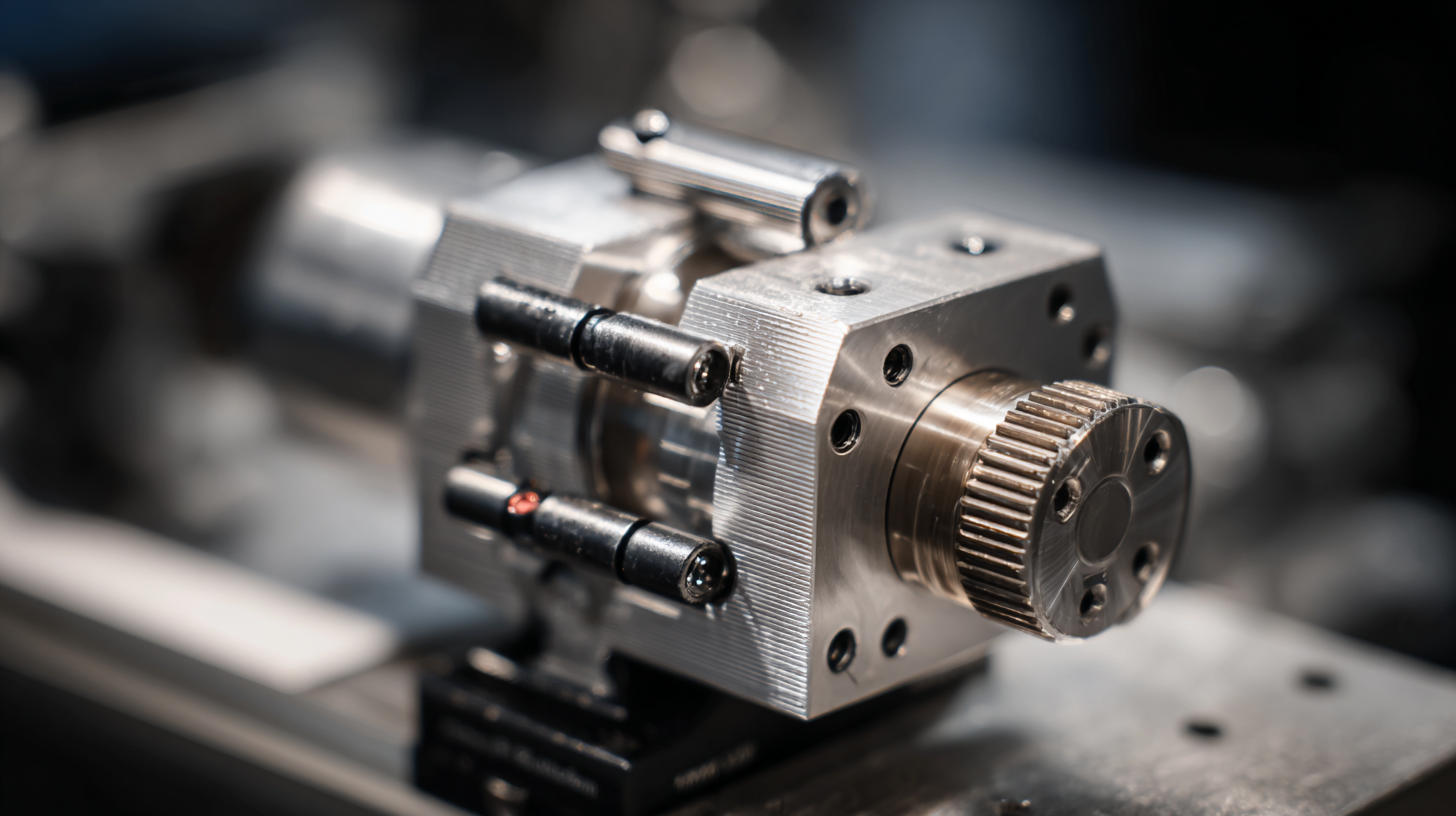

In the realm of modern design, metal prototyping solutions are at the forefront of innovation, driving remarkable advancements across various industries. Key technologies such as selective laser sintering (SLS) and electron beam melting (EBM) are transforming the way designers approach prototyping. These methods utilize high-powered lasers to fuse fine metal powders into intricate shapes, enabling the creation of complex geometries that were previously impossible or cost-prohibitive to achieve. As a result, designers can now explore more ambitious projects with greater flexibility and reduced lead times.

Moreover, advancements in computer-aided design (CAD) and additive manufacturing are enhancing the precision and efficiency of metal prototyping. Software tools that integrate with 3D printing processes allow for real-time adjustments and optimization, ensuring that the final product meets the exact specifications required. This synergy between design and technology not only streamlines the prototyping process but also significantly enhances the potential for innovative applications in sectors ranging from aerospace to healthcare. As technologies continue to evolve, the intersection of art and engineering in metal prototyping is set to unlock even greater possibilities for the future of design.

When it comes to metal prototyping, the decision between traditional and modern techniques can significantly impact the design process and final product. Traditional metal prototyping methods, such as sand casting and machining, have long been the go-to solutions for many engineers. These techniques offer a certain level of reliability and familiarity, allowing for precise control over dimensions. However, they can be time-consuming and may involve resource-intensive processes, which can delay product development and increase costs for businesses.

In contrast, modern metal prototyping solutions, such as additive manufacturing (3D printing), are revolutionizing the way designers approach their projects. These advanced techniques enable rapid prototyping, allowing for quicker iterations and more complex geometries that traditional methods may struggle to achieve. Additionally, modern approaches often require less material and generate less waste, aligning with contemporary sustainability goals. As companies increasingly seek innovative designs that push the boundaries of what is possible, leveraging state-of-the-art metal prototyping solutions can unlock new potentials and streamline the path from concept to creation.

Metal prototyping has emerged as a transformative process across various industries, enabling designers and engineers to bring their innovative concepts to life with precision and efficiency. In the aerospace sector, for instance, companies have successfully utilized metal prototypes to test and refine components under extreme conditions, significantly reducing lead times and costs while enhancing performance. One notable case involved a leading aerospace manufacturer that developed a complex turbine blade prototype, allowing for real-time adjustments and optimization before mass production, ultimately improving engine efficiency.

In the automotive industry, metal prototyping has been pivotal in streamlining the development of lightweight structures that enhance fuel efficiency. A renowned automotive brand recently launched an electric vehicle prototype utilizing advanced metal 3D printing techniques. This approach not only facilitated rapid iteration but also permitted the incorporation of intricate designs not feasible through traditional methods. The successful integration of these prototypes into the production process demonstrated how innovative metal solutions can drive significant advancements in functionality and sustainability.

Furthermore, the medical device sector has also seen remarkable outcomes through metal prototyping. A notable case involved the creation of customized surgical instruments through additive manufacturing. This approach allowed for the production of tools tailored to specific patient anatomies, improving surgical outcomes and reducing recovery times. By leveraging the capabilities of metal prototyping, companies are pushing the boundaries of design, ultimately leading to groundbreaking advancements across various fields.

| Industry | Application | Material Used | Prototyping Process | Benefits Achieved |

|---|---|---|---|---|

| Aerospace | Airframe Component Testing | Aluminum Alloys | Selective Laser Melting | Reduced weight, Improved strength |

| Automotive | Prototype Engine Components | Stainless Steel | CNC Machining | Faster design validation, Cost savings |

| Medical | Custom Surgical Tools | Titanium | Metal 3D Printing | Enhanced customization, Increased efficiency |

| Consumer Electronics | Chassis and Housing Units | Magnesium Alloys | Die Casting | Improved thermal management, Aesthetic finish |

| Industrial Equipment | Machinery Parts | Carbon Steel | Laser Cutting | Precision manufacturing, Higher durability |

As industries increasingly prioritize sustainable practices, the role of sustainability in metal prototyping innovations has gained significant attention. Modern prototyping solutions are now designed not only to enhance the efficiency of product development but also to minimize environmental impact. By leveraging advanced technologies like additive manufacturing and recycled materials, companies can significantly reduce waste associated with traditional prototyping methods. This approach not only conserves resources but also aligns with the global shift towards a circular economy, which emphasizes reuse and minimalism.

Moreover, sustainable metal prototyping is paving the way for innovative designs that cater to contemporary consumer demands for eco-friendly products. Designers are increasingly integrating sustainable practices into their workflows, utilizing materials that can be easily sourced, recycled, or returned to nature at the end of their life cycle. This shift not only improves a product's lifecycle but also enhances brand reputation among consumers who prioritize environmental responsibility. As the demand for sustainable solutions continues to rise, the integration of these principles into metal prototyping will likely lead to groundbreaking innovations that redefine the manufacturing landscape.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |