In the fast-paced world of manufacturing, achieving precision in rapid sheet metal fabrication has become a critical focus for companies striving to enhance productivity and reduce lead times. Rapid sheet metal fabrication techniques offer an efficient solution for creating complex components with high accuracy, enabling businesses to meet the ever-increasing demands of their customers. The integration of advanced technologies such as CNC machining, laser cutting, and 3D printing transforms traditional fabrication processes, allowing for quicker turnaround times without compromising quality.

This article explores various strategies and best practices that can be employed to maximize precision in rapid sheet metal fabrication, providing valuable insights for manufacturers looking to stay competitive in today’s dynamic market. From optimizing design for manufacturability to leveraging cutting-edge tools, our discussion will guide you through the essential steps to elevate your manufacturing capabilities and achieve superior results.

Rapid sheet metal fabrication techniques have revolutionized the manufacturing process by introducing speed and precision that traditional methods often lack. At the core of these techniques is a deep understanding of materials and their behaviors under different conditions. The use of computer-aided design (CAD) software allows engineers to model and simulate the fabrication process, ensuring that the design is not only feasible but also optimized for efficiency. This technology enables quick adjustments and iterations, significantly reducing lead times while maintaining high accuracy.

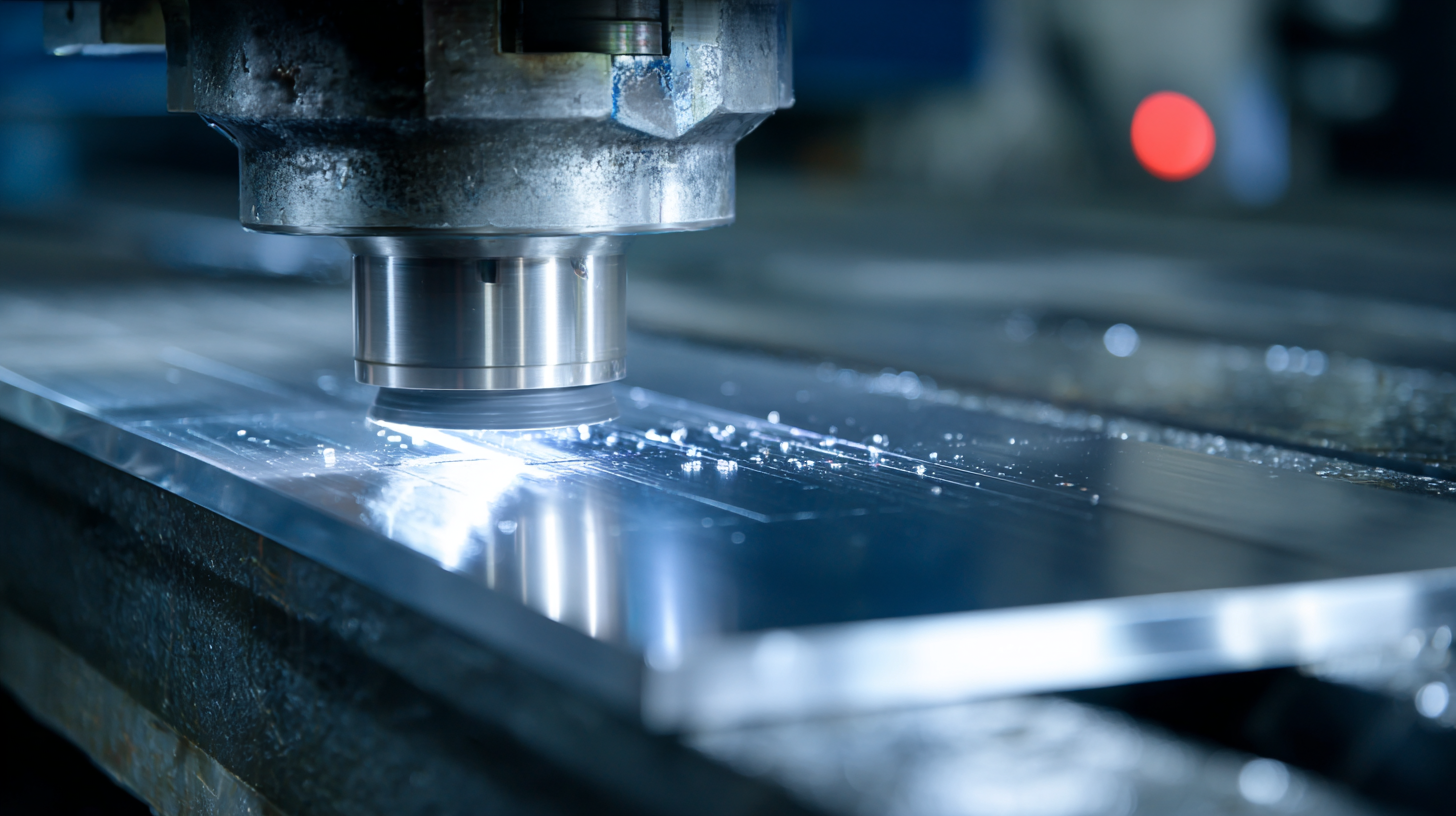

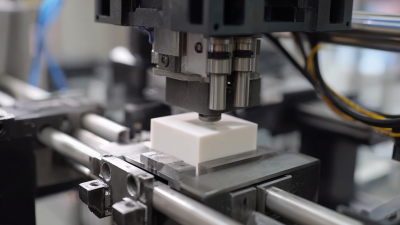

In addition, advanced machinery such as laser cutters and CNC machines play a crucial role in enhancing precision. These tools can execute complex designs with exceptional consistency, minimizing human error and material waste. Understanding the fundamentals of these machines, such as their operating principles and settings, is essential for achieving optimal results. Moreover, recognizing the importance of material selection and preparation can greatly affect the final product's quality, further emphasizing the need for a thorough understanding of rapid sheet metal fabrication techniques.

| Technique | Precision Level | Material Compatibility | Typical Applications |

|---|---|---|---|

| Laser Cutting | High | Stainless Steel, Aluminum | Aerospace, Automotive |

| Waterjet Cutting | Moderate | Glass, Plastics, Metals | Architecture, Signage |

| Punching | Moderate to High | Sheet Metal, Brass | Electrical Enclosures, HVAC |

| Bending | High | Steel, Aluminum | Frames, Brackets |

| 3D Printing | Variable | Plastics, Metals | Prototyping, Custom Parts |

Precision in sheet metal fabrication largely depends on the right tools and equipment. Utilizing advanced machinery, such as CNC (Computer Numerical Control) machines, allows for high accuracy in cutting and shaping metal sheets. These machines can execute complex designs with minimal human intervention, ensuring consistent quality and reducing the likelihood of errors. Additionally, laser cutting machines provide a clean edge and precise dimensions, making them an invaluable asset in rapid fabrication processes.

To achieve optimal results, it is also essential to incorporate tools like hydraulic presses and brake presses. Hydraulic presses enable efficient bending and shaping of metal sheets, while brake presses allow for precise angle control during bending operations. Furthermore, high-quality measuring instruments, such as calipers and laser measurement systems, are vital for checking dimensions and ensuring that each component meets the required specifications. With the integration of these essential tools and equipment, manufacturers can enhance their precision and efficiency in rapid sheet metal processing.

In order to achieve precision in rapid sheet metal fabrication, several key design considerations must be taken into account. First and foremost is the importance of material selection. According to a report by the Fabricators & Manufacturers Association, the choice of material can significantly affect the final accuracy of fabricated parts. For instance, using high-quality stainless steel often yields better dimensional tolerances compared to lower-grade materials. This is due to the consistency in the material properties, which reduces warping and distortion during the fabrication process.

Another critical design consideration is the incorporation of CAD software early in the design phase. Advanced CAD systems enable designers to simulate the fabrication process, allowing for adjustments and optimizations before production begins. According to a survey conducted by SME (Society of Manufacturing Engineers), 70% of manufacturers reported improved accuracy and reduced waste when employing such technological tools. Additionally, considerations for tool selection and machining parameters, such as cutting speed and feed rate, can influence the precision of the final product. By meticulously addressing these factors, manufacturers can significantly enhance the accuracy of rapid sheet metal fabrication processes.

Achieving high-quality results in rapid sheet metal fabrication relies heavily on effective quality control practices. One of the best practices is implementing a rigorous inspection process at every stage of production. This includes initial material assessment, in-process checks, and final product evaluations. By utilizing tools such as calipers, gauges, and laser measurement systems, manufacturers can ensure components meet precise specifications and tolerances, minimizing the risk of defects.

Another essential aspect of quality control is maintaining clear documentation throughout the fabrication process. This involves keeping detailed records of machine settings, material properties, and inspection results. Such documentation not only facilitates traceability but also serves as a valuable resource for process improvement. Regularly reviewing these records allows teams to identify patterns, address recurring issues, and refine their fabrication techniques, ultimately leading to higher precision in the final products.

Achieving precision in rapid sheet metal fabrication is significantly enhanced through the strategic use of technology. Advanced software tools, such as CAD and CAM systems, enable engineers to create detailed designs that minimize errors. These tools not only streamline the design process but also facilitate the simulation of fabricating processes, allowing for adjustments before physical production begins. By embracing such technology, manufacturers can ensure that components are produced with high accuracy, ultimately leading to better fit and function in the final assembly.

Tips: Invest in high-quality software to improve design accuracy and reduce the time needed for revisions. Regularly update your technology to ensure compatibility with the latest manufacturing processes.

In addition to software, incorporating advanced machinery like laser cutters and CNC machines plays a critical role in enhancing precision. These machines offer cutting capabilities that are consistently accurate and repeatable, which is essential in high-volume production scenarios. By integrating automation into the fabrication process, companies can achieve tighter tolerances and higher efficiency, reducing material waste and production time.

Tips: Schedule routine maintenance for your machines to maintain peak performance and precision. Consider training staff on the latest technologies to maximize operational efficiency.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |